Selective and reversible adsorption of gases

Things are much better under tension

Advertisement

Using an electrically switchable composite of carbon and silicon dioxide, a research team at TU Darmstadt has for the first time specifically removed gases such as carbon dioxide, nitrogen or argon from the gas phase - simply by applying an electrical voltage. The material stores the gases on its surface and releases them again completely when the voltage changes. The study opens up new perspectives for energy-efficient separation processes and has now been published in Advanced Science.

In science and technology, it is of central importance to separate substances from one another. If you want to separate liquids, for example, this often requires a lot of energy, such as during distillation and evaporation.

However, there are also gentler methods for separating substances. These work by attaching substances (adsorbates) to a surface and removing them again later. In several steps, for example, different gases can be captured (adsorbed) and released again (desorbed) one after the other.

In order to realize adsorption and desorption in an energy-efficient manner, switchable materials and processes are required. The switchable material must also be readily available for technological use. The switching process should be reversible and use as few resources as possible. To this end, application-oriented research is focusing in particular on electrical processes. The process is particularly attractive if the necessary electrical energy can be provided from renewable sources as far as possible.

A research team led by doctoral student Silvio Heinschke and Professor Jörg J. Schneider from the Department of Mesoscopic Chemistry in the Chemistry Faculty at TU Darmstadt has now succeeded for the first time in adsorbing carbon dioxide (CO₂), nitrogen (N₂) or argon directly from the gas phase by applying a low electrical voltage to a material (adsorbent). This adsorbent consists of carbon (coal) and silicon dioxide (sand). Later, these gases can be removed from the adsorbent material in a controlled and complete manner by removing the voltage again.

The trick is that interfaces of only a few micrometers in size are created in the material. These interfaces are created between the electrically conductive carbon and the dielectric, i.e. insulating, silicon dioxide. The mixture (composite) of both materials is necessary and decisive for the adsorption/desorption behavior now described for the first time.

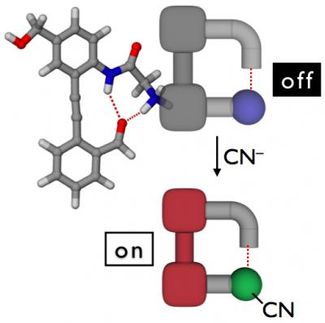

Inhomogeneities, i.e. field gradients, are generated between the numerous interfaces of carbon and silicon dioxide in the composite by electrical charging. In these fields, gas molecules such as CO₂, N₂ or argon are slightly electrically charged or polarized and then adhere to the surface of the carbon.

Adsorption is influenced by the multipoles in the gas molecules. These have different charge distributions and polarizabilities in the electric field. The resulting binding of the gases to the adsorbent is completely reversible. Thus, by switching the electric field on and off, a voltage-induced swing can be generated between the charge and discharge from the gas phase and the composite surface.

In principle, this principle should be feasible for all gases with a high polarizability. On this basis, the separation of gas mixtures by electrically controlled swing adsorption/desorption also appears realistic in the future.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.