Bayer MaterialScience: Intelligent technology improves energy efficiency

New industrial production process: Significant reduction in electricity consumption and CO2 emissions

Advertisement

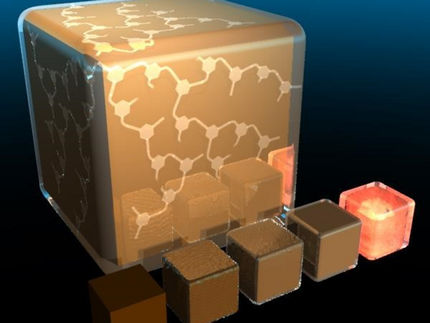

With the introduction of a new industrial manufacturing process, Bayer MaterialScience is poised to significantly reduce energy consumption and cut CO2 emissions. At the Chempark Krefeld-Uerdingen site, a demonstration plant with an annual capacity of 20,000 metric tons of chlorine has gone on stream. The oxygen depolarized cathode technology used for this has been incorporated into the new electrolysis technology from Uhde/UHDENORA. The combination of the two technologies was developed at Bayer in Leverkusen over the past eight years. Provided the two-year large-scale trial is successful, Bayer will gradually switch its chlorine production to the new process. In addition, the companies will also offer the new technology to the global market. Large German chlorine producers have already announced their interest, as have a number of companies in the Asia/Pacific region.

"Improving energy efficiency in chemical production processes can considerably reduce electricity consumption in Germany and elsewhere in the world," said Patrick Thomas, Chief Executive Officer Bayer MaterialScience. "In the present-day debate, the subject of energy efficiency is not being given enough air-time. Politicians should focus their attention not only on generating electricity but also on how to significantly lower electricity consumption with comparatively little effort."

In model calculations, experts have concluded that were the Bayer with the Uhde/UHDENORA technology to be used only throughout Germany, it would save enough electricity to supply a city as large as Cologne, a city with more than one million inhabitants. This corresponds to the power generated by a 700-megawatt power plant. Patrick Thomas is calling on politicians to support not only the development of energy-efficient production processes, but also to actively support the widespread application of such technologies in industry. Thomas: "With the right incentives, enormous energy savings would be possible here within a short period of time. As a pioneer in this field, Germany could send out a clear signal in matters of energy efficiency."

Most read news

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.