Borealis Schwechat celebrates 50 years of polypropylene production

Advertisement

In October, Borealis celebrated an important anniversary with the 50th anniversary of polypropylene (PP) production at its Schwechat location.

The company’s first PP production plant became operational in Schwechat in 1961 and received the designation PP1. At that time, the plant was part of the Danubia Petrochemie AG and was not merely the first of its type at the company, but also only the second such installation worldwide. Initially the propylene raw material required for PP manufacture was delivered in railway wagons in a somewhat complicated procedure, but subsequently the gas was supplied directly via pipelines from the neighbouring OMV refinery.

“The plant employed the so-called Montecatini process and for the time had an impressive annual capacity of 4,500 tonnes, explains Rudolf Sukal, Borealis Location Leader Schwechat. He continues, “Today, a modern plant can produce the same amount of polypropylene in less than a week.”

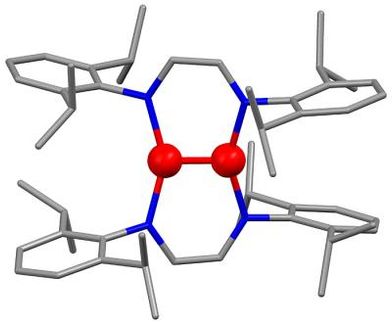

Catalysts constitute the key component in plastics manufacturing and in Schwechat a Ziegler-Natta model was employed. This type of catalyst, which in 1963 won the Nobel Prize for the Italian chemist Giulio Natta, is still utilized for plastic production today.

The first product quality manufactured in the PP1 plant in Schwechat was Daplen™, which was mainly further processed into household articles by means of injection moulding. The material from the 1970s has been further developed and Borealis continues to produce Daplen, which is now used primarily in the automotive sector.

PP1 remained in operation until 2000. At the time of its shutdown, it had an annual production capacity of 70,000 tonnes. Today, the Borealis plant in Schwechat is one of the most modern and important in Europe with a workforce of around 500 and annual production capacity of roughly one million tonnes of plastics.

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.