Clariant launches biofuel of the future

Clariant inaugurated Germany's biggest pilot plant for the production of climate-friendly cellulose ethanol from agricultural waste. Located in Straubing, Bavaria and supported by the Bavarian government and the Federal Ministry for Education and Research, the futuristic project will produce up to 1,000 tonnes of cellulose ethanol from around 4,500 tonnes of wheat straw based on the sunliquid® technology developed by Clariant. It represents an investment of around 28 million euros. Studies show that Germany potentially has around 22 million tonnes of straw that could be used for energy production without compromising essential soil regeneration. This would be sufficient to cover around 25% of Germany’s current gasoline requirements.

In the presence of Federal Minister Annette Schavan and the Bavarian Minister of Economic Affairs, Martin Zeil, Clariant CEO Hariolf Kottmann declared: "The inauguration of the new plant marks an important milestone in the production of a climate-friendly biofuel that can also be used as a raw material for the chemical industry." Kottmann appealed to politicians and industrialists to draw lessons from the failed start-up of biofuel E10 and to seek open dialogue with all interested parties. "Only when society recognizes the environmental benefits of climate-friendly biofuels can second-generation bioethanol be successful ." Kottmann called for stable and reliable framework conditions and an extension of the tax exemption status for second-generation biofuels beyond 2015.

Professor Andre Koltermann, Head of Clariant's Biotech & Renewables Center, added: "We have been developing the sunliquid technology since 2006 and have been testing the method on a pilot scale since 2009." In an area encompassing approximately 2,500 square meters, all the process steps will be performed that will later be used in an industrial-scale plant; the aim of which is to confirm the technological feasibility of the sunliquid technique. "The results we obtain in Straubing will enable us to plan industrial production plants efficiently and economically, and ultimately to realize such plants in cooperation with partners," continued Koltermann.

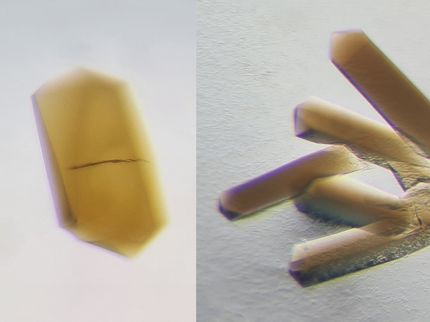

The sunliquid process is an innovative biotechnological method that turns plant waste products such as grain straw and corn straw into second-generation cellulose ethanol.

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.