Cool it, quick: Rapid cooling leads to stronger alloys

Researchers reveal a new technique to produce high strength metallic alloys, at a lower cost using less energy

Advertisement

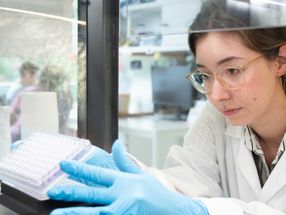

A team of researchers from the University of Rostock has developed a new way to rapidly produce high strength metallic alloys, at a lower cost using less energy than before. It's expected that this breakthrough will profoundly change how we produce components used in a diverse range of applications; including transport and medical devices.

The research, which appears in Materials Today, reports on the first Spark Plasma Sintering (SPS) system with an integrated gas quenching mechanism, capable of alternating the phase compositions and retaining the smallest grain features inside a structured metallic alloy.

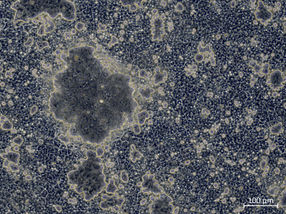

SPS is a technique used to fuse fine powders into a dense solid material, by placing powder into a mold (or die) and simultaneously applying pulses of electric current and mechanical pressure to it. By varying SPS cooling rates, it is possible to control the phase and grain sizes in a material, and so, to tune its mechanical properties. In their study, the team of researchers led by Dr. Eberhard Burkel, a Professor of Physics of New Materials, demonstrated that rapidly cooling a material directly after SPS fabrication can produce a material with enhanced hardness, strength and ductility.

The new rapid cooling SPS system is based on a commercially available design, modified to include a series of gas inlet nozzles. After sintering, most SPS systems are left to cool naturally, or are flooded with argon gas. The system blasts nitrogen gas into the chamber at high speeds, rapidly cooling the material.

To demonstrate the utility of the system, Grade 5 Titanium (Ti-6Al-4V) – known as the "workhorse" of the titanium industry – was produced at different cooling rates. The most-rapidly cooled alloy was found to be up to 12% harder than the naturally-cooled alloy, and with an improved ductility up to 34±3%. Ti-6Al-4V is the most common titanium alloy in use worldwide, with applications in the aerospace, biomedical and marine industries.

In their article the researchers explain, "This high-ductile alloy offers unprecedented opportunities for the easy manufacturing of complex shapes for biomedical and new engineering applications."

Original publication

Faming Zhang, Michael Reich, Olaf Kessler and Eberhard Burkel; "The potential of rapid cooling spark plasma sintering for metallic materials"; Materials Today, Volume 16, Issue 5, Page 192-197 (2013)