Researchers crack 50-year-old nuclear waste problem, make storage safer

Advertisement

Researchers at the University of North Carolina at Chapel Hill have adapted a technology developed for solar energy in order to selectively remove one of the trickiest and most-difficult-to-remove elements in nuclear waste pools across the country, making the storage of nuclear waste safer and nontoxic -- and solving a decades-old problem.

The work, published in Science, not only opens the door to expand the use of one of the most efficient energy sources on the planet, but also adds a key step in completing the nuclear fuel cycle -- an advance, along with wind and solar, that could help power the world's energy needs cleanly for the future.

"In order to solve the nuclear waste problem, you have to solve the americium problem," said Tom Meyer, Arey Distinguished Professor of Chemistry at UNC's College of Arts and Sciences, who led the study.

Americium doesn't have the same name recognition as a plutonium and uranium, but researchers have been trying to remove it from nuclear waste for decades. Several groups initially succeeded, only to be met with several subsequent problems down the line, rendering the solution unfeasible. Meyer and his team, including Chris Dares, who spearheaded the project, have found a way to remove the radioactive element without encountering downstream problems that have hindered progress.

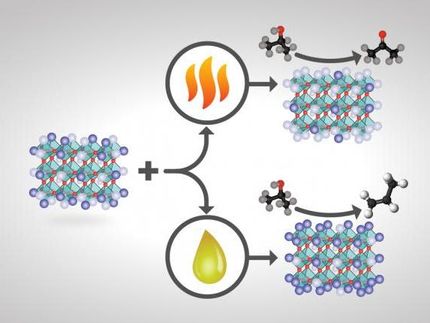

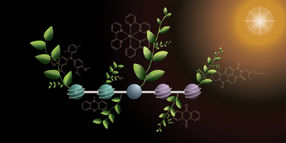

The technology Meyer and Dares developed is closely related to the one used by Meyer at the UNC Energy Frontier Research Center of Solar Fuels to tear electrons from water molecules. In the americium project, Meyer and Dares adapted the technology to tear electrons from americium, which requires twice as much energy input as splitting water. By removing those three electrons, americium behaves like plutonium and uranium, which is then easy to remove with existing technology.

Dares describes that nuclear fuel is initially used as small solid pellets loaded into long, thin rods. To reprocess them, the used fuel is first dissolved in acid and the plutonium and uranium separated. In the process, americium will either be separated with plutonium and uranium or removed in a second step.

Meyer and Dares worked closely with Idaho National Laboratory (INL), who provided research support and technical guidance on working with nuclear materials. Most of the experiments were carried out in the laboratories at Idaho, which provided a safe area to work with radioactive material. At present, INL and UNC-Chapel Hill are in discussion about extending the research and to possible scale up of the technology.

"With INL working with us, we have a strong foundation for scaling up this technology," said Dares. "With a scaled up solution, not only will we no longer have to think about the dangers of storing radioactive waste long-term, but we will have a viable solution to close the nuclear fuel cycle and contribute to solving the world's energy needs. That's exciting."

Most read news

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

PolyOne and Nanocor form Strategic Alliance to Produce, Market Nanocomposite Plastics

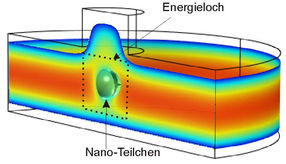

'Goldilocks material' could change spintronics

Bayer chairman at the helm of the German Chemical Industry Association - Marijn Dekkers is the new VCI President

Compounds made from ‘digested’ molecules feeds appetite for greener pharmaceuticals and agrochemicals - New method uses enzymes to produce indolic amides, carboxylic acids and auxins – vital for use in pharmaceutical and agrochemical industries

SIMONA to acquire Boltaron - Second acquisition in North American market

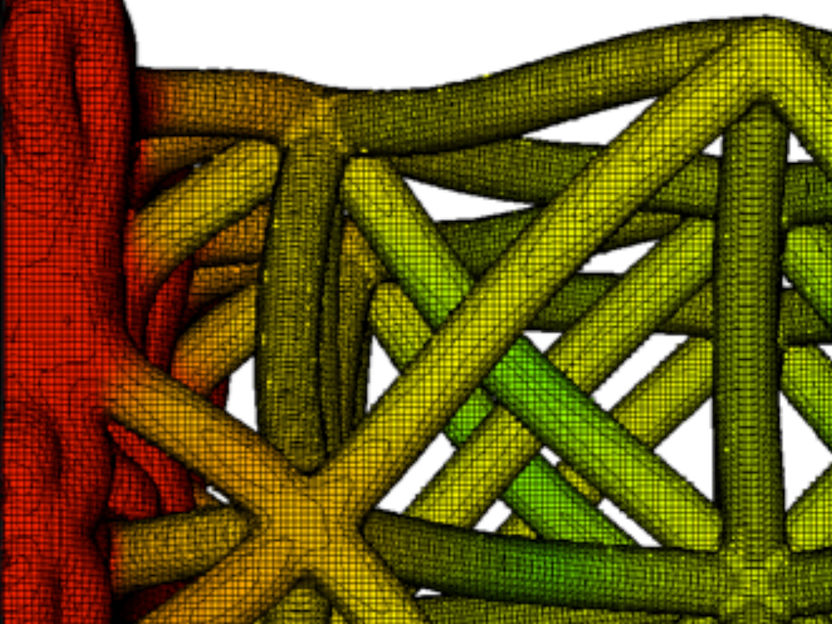

Putting pressure on 3D-printed structures

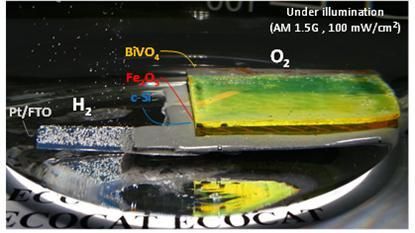

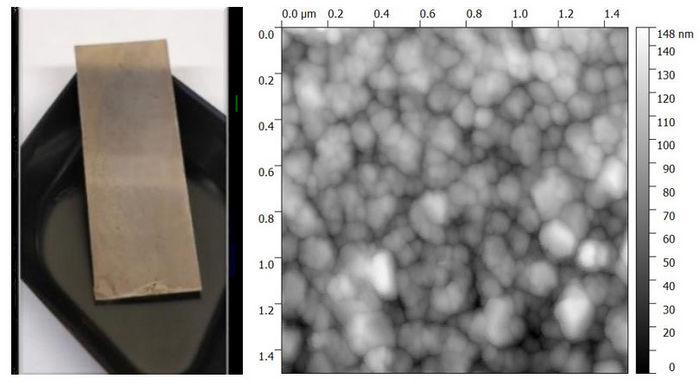

Artificial leaf goes more efficient for hydrogen generation

Enhanced arsenic detection in water, food, soil - Sensor can identify the global content and form of arsenic-containing molecules at very low concentrations

Lurgi to build the largest edible oil plant in Europe and the CIS