Cars to be lighter with composite parts from Ultratect®

High-temperature resin 50% lighter than steel equivalent

AC.S and Jacob Composite (Wilhelmsdorf, Nürnberg, Germany) have developed and manufactured the first production part using Ultratect®, a thermoplastic structural foam derived from BASF's high-temperature Ultrason® E resin. The part concerned is found in the rear seat backrest on the new BMW M3 CSL, which first appeared at the Geneva motor show in March 2003.

At 5.5 kilos, the new foam composite part is half the weight of the conventional steel structure, yet exhibits equally good crashworthiness and better vibrational dampening.

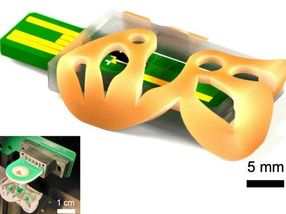

The part The main component of the backrest in the M3 CSL consists of a 25-mm core of Ultratect® foam sandwiched between 1-mm sheets of polypropylene reinforced with continuous glass filament. The part is made by heat-forming the polypropylene sheets onto the cold foam in a mould. This single-step operation also includes the application of a needled-felt covering to the rear-side of the backrest. The whole process takes only 1.5 minutes and so is fast enough for mass production.

AC.S (Advanced Composite Systems GmbH) manufactures the Ultratect® foam under license and supplies this and the polyproplyene sheet semifinished to Jacob Composite GmbH, who produce the finished backrests, to include ABS trim and thin padding.

Ultratect® foam Ultratect® is a foamed version of BASF's Ultrason® E polyethersulfone high-temperature thermoplastic. It combines Ultrason E's extraordinarily high temperature/chemical resistance and good fire performance with the low density and high energy-absorption properties of foam. Such characteristics enable Ultratect® to be used in numerous other applications in the transport sector, including rail vehicles, aircraft and ships, where resistance to heat and chemicals, fire safety, rigidity and lightness are major requirements. Ultratect® can withstand temperatures of up to 210°C, making it the most heat resistant thermoplastic foam currently on the market.

Most read news

Topics

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.