Altis Semiconductor Selects SiLK resin from Dow for 0.13 micron Copper Chip Production

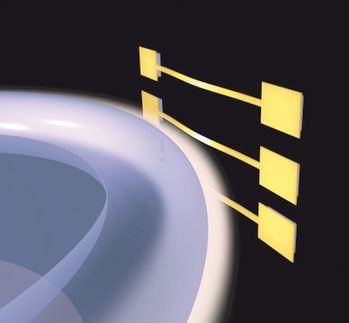

Altis Semiconductor, a joint venture of IBM Microelectronics and Infineon Technologies, will implement a low-k process utilizing SiLK resin to produce 0.13-micron custom logic chips for telecommunications, computer peripherals and wireless applications. Used in combination with high-speed copper interconnects, SiLK resin enables electrical signals to propagate 37 percent faster than conventional technologies while using less power.

Altis Semiconductor, one of the first European chipmakers to adopt a low-k material, is currently running a pilot manufacturing line at its semiconductor fab in Corbeil-Essonnes, France. Volume production and customer delivery is slated for year-end 2001.

"After extensive evaluation, we chose SiLK resin for our next-generation copper process because the spin-on material met the range of critical thermal, mechanical and chemical properties requirements for integration into copper interconnect fabrication," said Caroline Boulenger, senior process engineer at Altis Semiconductor. "SiLK resin with copper provides significant improvement in device performance compared to aluminum/silicon dioxide. And, we believe by integrating SiLK resin now, we will be able to leverage our investment in low-k as we transition to 0.10-micron technology."

"Altis Semiconductor’s commitment to SiLK resin demonstrates the growing momentum behind the adoption of low-k materials," said Martin Meier, business development director, Advanced Electronic Materials, Dow Europe. "It also reinforces the growing acceptance of SiLK resin, and further augments our leadership position in the low-k market."

SiLK resins were specifically developed by Dow for use as an interlayer dielectric (ILD) material for high-performance integrated circuits. The spin-on organic polymer features a low isotropic dielectric constant of 2.6 that helps chipmakers increase the speed and performance of their chips by enabling denser circuitry.

Dow offers a family of SiLK resins with k = 2.6 for both copper dual-damascene processing and aluminum/tungsten gapfill technologies. SiLK resins are stable at temperatures up to 450° C (842° F), and have the highest glass transition temperature (Tg > 490° C) among all organic candidates evaluated for ILD applications. The dielectric material is compatible with CVD or electroplated copper and has an etch selectivity ratio greater than 20:1 vs. hardmask.

Dow’s Advanced Electronic Materials business provides a variety of materials and technologies to support customer innovation in the electronics arena. Positioned for growth and service, Dow has a world-scale commercial plant in Midland, Mich., for the manufacture of SiLK resins, and an expanded clean room facility in Auburn, Mich.

Most read news

These products might interest you

Good Weighing Practice by Mettler-Toledo

Your Concrete Weighing Quality Assurance Plan

GWP Verification service

Milli-Q® Services / MyMilli-Q™ by Merck

Services & Support for Water Purification Systems

Quality Care, Delivered. In Person & Online

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.