How gas bubbles influence hydrogen production

New findings are relevant for all electrolysis processes

Advertisement

electrolysers are a key technology for the energy transition. They split water into hydrogen and oxygen, but still consume too much electricity in the process. One challenge is that the initially dissolved hydrogen separates in the form of gas bubbles, which can seal off the electrode - at the expense of efficiency. A German-Dutch research team led by the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) has now gained unique insights into the interior of the hydrogen bubbles and derived new findings for the processes in the electrolyzer. The results have been published in the journal Nature Communications.

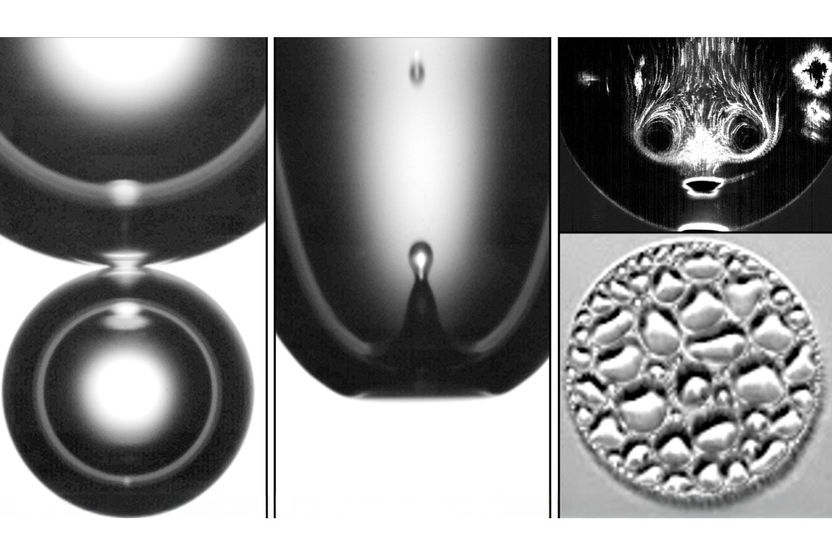

The series of images shows how two hydrogen bubbles combine to form a larger bubble during water electrolysis in an acidic electrolyte (coalescence). This creates a liquid jet of electrolyte inside the new bubble, which becomes unstable and breaks up into individual droplets (center). As this process happens very frequently, a fine spray of electrolyte droplets is produced. In the top right-hand image, streamlines are shown which illustrate the movement of these droplets within the bubble. The droplets sink downwards and collect at the base of the hydrogen bubble. There they form small puddles of liquid, which re-wet the electrode and change the shape of the bubble contact line. This can cause the bubble to detach from the electrode earlier (right-hand image below).

Gas bubbles in electrolysers cause hydrogen production to consume too much electricity, which makes the process much more expensive. "Understanding the dynamics of gas bubbles is an important piece of the puzzle if we want to make electrolysers more efficient. We have now taken a significant step forward because we have been able to analyze the processes inside the gas bubbles for the first time," explains Prof. Kerstin Eckert, Director at the HZDR Institute of Fluid Dynamics.

Droplets discovered in gas bubbles - the inside becomes visible

The main new finding: the hydrogen bubbles do not always consist of pure gas. They can also contain a fine spray of micro-droplets of the electrolyte, i.e. the liquid with which the electrolyser is operated, for example potassium hydroxide solution. This phenomenon allows deeper insights into the physico-chemical and hydrodynamic processes involved in water electrolysis.

The study provides unique insights into the inside of the bubbles: "Using our team's optical methods, we were previously unable to see the flows in the gas itself. Now we can follow them via the droplets in the gas bubbles because they move along with the gas," explains Dr. Gerd Mutschke from the HZDR. In a shadowing process, the bubble is illuminated with a parallel beam of light. A camera is positioned behind it and images the gray value distribution of the bubble. The microdroplets in the gas appear as black dots. An additional laser light section uses the microdroplets as tracers to measure the flow field inside the bubble.

Dr. Aleksandr Bashkatov, then a doctoral student in Eckert's team, then a postdoctoral researcher at the University of Twente on a joint Dutch-German project and now at RWTH Aachen University and first author of the study, first noticed the droplets in the gas during parabolic flight experiments in zero gravity. Building on this, the team carried out further experiments on Earth and simulations to understand the exact mechanism of how the electrolyte gets into the gas bubbles.

Swirling currents inside and outside

At the electrodes, many tiny microbubbles initially form a kind of carpet and then merge quickly one after the other with a large bubble. Part of the surface energy of the small bubbles is converted into kinetic energy and can deform the interface between the gas and electrolyte to such an extent that electrolyte liquid penetrates the bubble. The liquid is injected into the large bubble at high speed in the form of a "microjet", where it disintegrates into a cloud of tiny droplets that swirl through the bubble following the internal flow. Physically, the vortices are created by a thermal Marangoni effect at the interface between the gas bubble and the electrolyte: high current densities heat the interface locally and thus reduce its surface tension.

"We have discovered a fantastic fundamental phenomenon, the exact effects of which on the technology cannot yet be quantified. But the gas bubbles and how they fuse together are a technologically relevant problem in all electrolyser architectures - so there is a lot to do," summarizes Eckert. The German-Dutch follow-up project ALKALAMIT, funded by the Federal Ministry of Education, Research, Technology and Space (BMFTR) and the Netherlands Organization for Scientific Research (NWO), which Eckert is coordinating on the German side, is expected to provide further insights.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Original publication

Aleksandr Bashkatov, Florian Bürkle, Çayan Demirkır, Wei Ding, Vatsal Sanjay, Alexander Babich, Xuegeng Yang, Gerd Mutschke, Jürgen Czarske, Detlef Lohse, Dominik Krug, Lars Büttner, Kerstin Eckert; "Electrolyte droplet spraying in H2 bubbles during water electrolysis under normal and microgravity conditions"; Nature Communications, Volume 16, 2025-5-16