GE Expands Production Capacity to Meet Strong Demand for Advanced NXT Silane

Advertisement

GE announced that it has expanded its capacity for high technology silanes used in the production of silica tires and other high-performance products. Using a proprietary process designed by GE engineers, production start-up commenced in the third quarter of 2004, and last week additional capacity was brought on-line to meet the high demand for this new technology. GE's NXT silane is produced at a plant in Texas City, Texas. GE declined to disclose its investment in the new capacity for competitive reasons.

NXT silane is a patented GE molecule that helps circumvent the long, slow, multi-step process required when traditional silanes are used to mix silica with rubber for silica tires. Production line throughput can be improved because silica tire compounds can be processed hot, hard, and fast when NXT silane is used.

GE estimates that the tire industry could potentially realize several hundred million dollars in manufacturing cost savings with the new NXT silane technology. "With raw material prices escalating, the NXT silane family of products may offer tire manufacturers significant cost reductions in other areas," said Wayne Hewett, president and CEO of GE Advanced Materials-Silicones.

Most read news

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Johann_Sigismund_Elsholtz

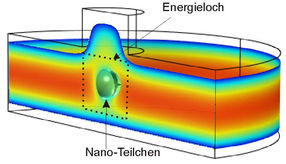

NIST develops novel ion trap for sensing force and light

Discovery brings all-solid-state sodium batteries closer to practical use - Process that can lead to mass synthesis yields solid sulfide electrolyte with world’s highest reported sodium ion conductivity

Category:Davy_Medal