Rohm and Haas Electronic Materials develops electrolytic hard gold plating process that reduces gold consumption

Advertisement

Rohm and Haas Electronic Materials announced the development of "RONOVEL(TM) CS100," a new electrolytic hard gold plating solution that is capable of minimizing gold deposition onto unwanted areas during gold plating of components, such as connectors.

Today gold plating is extensively used in electronic equipment and electronic components due to its excellent electrical properties and corrosion resistance. In particular, hard gold plating (Au-Co alloy), which provides high hardness, low contact resistance and superb wear resistance, is a product and technology essential for making reliable contacts in connectors and switches. As a connector finish, hard gold is required to maintain high electrical performance over extended periods of time. However, since gold plating is expensive, it is increasingly required to achieve thinner films over increasingly smaller areas of deposition. To respond to such demands, the industry is making improvements such as increased mask accuracy of the plating systems. Naturally, it is a significant benefit if plating solutions are able to suppress deposition onto those areas that are not specified to be plated.

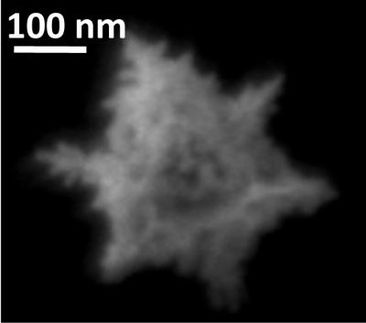

RONOVEL(TM) CS100 plating process is designed to electrolytically deposit a Au-Co alloy suitable for electronic applications. According to the company, deposits produced from the plating process meet the requirements of ASTM B-488 Type 2, 3 Code C, D. Since the process uses a low gold metal content (standard gold metal concentration is 4 g/L) and is still capable of achieving a large operating current density range of 5 to 60 A/dm2, the solution helps reduce drag-out costs. In addition, it minimizes "bleed" deposition under masked areas while reducing immersion plating, due to the use of a special additive designed for this purpose. As a result, the RONOVELTM CS-100 plating process succeeds in drastically reducing deposition onto unwanted areas in partial plating applications, such as spot plating.

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Carbon_group