Ciba Specialty Chemicals and Max Planck Institute to develop novel materials for printable organic electronics

Advertisement

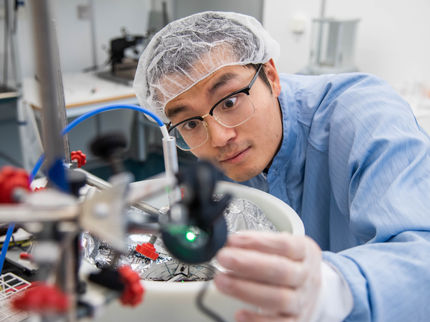

Ciba specialty chemicals and the Max Planck Institute for Polymer Research have agreed to collaborate in the research of conductive materials for printable electronic materials. The three-year, multidisciplinary project focuses on the development of novel conductive polymers for printable applications. This collaboration is expected to speed up the introduction of improved materials. The production of devices such as sensors, photovoltaic cells, Radio Frequency Identification (RFID) tags, Organic Light Emitting Diodes (OLEDs) and other electronics shall benefit considerably from printing as against other techniques, such as etching.

"The collaboration is part of our strategy to strengthen Ciba Specialty Chemicals' research network in the fast-developing field of advanced functional materials for the electronic industry. Printable organic electronics offer great opportunities for new electronic devices. However, the performance, durability and handling requirements of the conductive materials currently available are not yet adequate for many major applications. Groundbreaking development work in this highly interdisciplinary field is still needed," says Martin Riediker, Chief Technology Officer of Ciba Specialty Chemicals.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.