Genencor and Goodyear to co-develop renewable alternative to petroleum-derived isoprene

Collaborative research marks a leap forward for the biochemicals market segment and the biobased economy

Advertisement

Genencor, a division of Danisco A/S and The Goodyear Tire & Rubber Co. announced a research collaboration to develop a breakthrough biobased process for producing isoprene using renewable raw materials.

Goodyear and Genencor are developing BioIsoprene™, a biobased alternative for the petroleum-derived chemical compound isoprene. BioIsoprene™ can be used for the production of synthetic rubber — -which in turn is an alternative for natural rubber — and other elastomers. The development of BioIsoprene™ could make the tire and rubber industry less dependent on oil-derived products, such as synthetic rubber made from petroleum-derived isoprene monomer.

Danisco bases its investment on conservative estimates, placing the annual world market potential for high purity isoprene at a value of US $1-2 billion. BioIsopreneTM will address this market as a renewable and cost-competitive alternative to petroleum-derived isoprene which is currently used in the production of synthetic rubber for tire applications, adhesives, elastomers and other styrene applications.

Genencor plans to manufacture and supply Goodyear with BioIsopreneTM through a strategic supply arrangement. According to the company, Goodyear is one of the world’s largest users of isoprene for the production of synthetic rubber and other elastomers. Sales of BioIsopreneTM by Genencor to third parties are also anticipated for all market applications of high purity isoprene.

Danisco and Goodyear have been investing jointly for more than a year to validate the project, establish the teams, and secure intellectual property assets. To date, our technical progress has exceeded expectations. Over the next three years, Danisco will invest approximately $50 million to continue technology development, scale-up and deliver manufacturing cost targets. Additional investments to establish pilot plant operations and manufacturing infrastructure are expected. We expect technical readiness by 2010 and commission of the first large-scale manufacturing plant by 2012.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

EPC Contract for an Amine Plant Signed With Aker Clean Carbon AS

NIST gets the dirt on soil with 3 new reference materials

WACKER Further Expands its Production and R&D Capacities in China

TGen scientists uncover new field of research that could help police in crime scene forensics - Resolving individuals contributing trace amounts of DNA to highly complex mixtures using high-density SNP genotyping microarrays

LANXESS acquires PTAP product line - Broadening active ingredient range for disinfectants

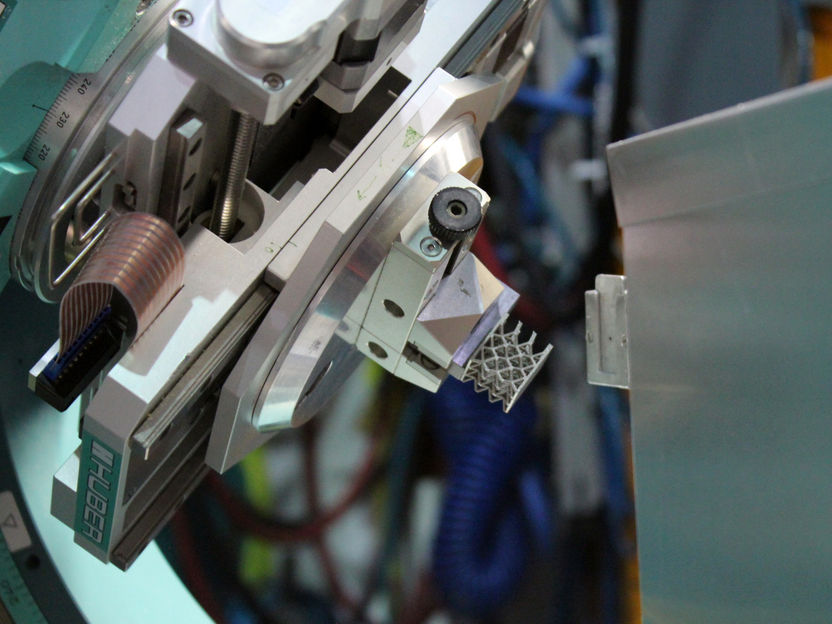

Energy-saving gas turbines from the 3D printer - Neutrons "see" internal stress in components from additive manufacturing

Vinnolit zieht zweite Stufe der Chlorkonversion vor - Umrüstung der Elektrolysen in Gendorf und Knapsack auf Membrantechnologie bereits bis Mitte 2009