Carolina Turkeys relies on BOC technology to reduce water consumption

Murray Hill, New Jersey, US, March 5, 2002— Carolina Turkeys became the first Turkey processor to take advantage of the financial and resource savings made possible by BOC’s innovative Macron™ Loop Process water Resource System. The patented, ozone-based system, which has been used primarily in U.S. broiler plants since its introduction in 1999, can reduce turkey processor water consumption by millions of gallons per month, saving customers tens of thousands of dollars annually.

Availability of water used in the poultry and turkey processing industries has become a major problem. The cost of incoming water has risen along with the cost of discharging water. Even when water resources are available, the public demands that companies exercise proper stewardship of limited resources. At the same time, stricter food safety regulations have resulted in a dramatic increase in the amount of process water consumed in U.S. poultry plants.

Mike Bliss Vice President of Operations, Carolina Turkeys, states, "We were exceeding our hydraulic loading levels and needed to find ways to reduce water use without sacrificing the food safety benefits that bird washing provides. After looking at different systems, we decided to turn to the Macron Loop for assistance. Today through improved management practices and the installation of a water re-use system, we have reduced our water consumption by 20 to 25 percent, while maintaining our high standards of food safety."

Carolina Turkeys installed and commissioned the Macron™ Loop system at its Mount Olive, North Carolina plant during the fall of 2001.

"The Macron™ Loop Process Water Reuse System can reduce water consumption by anywhere from 4 million to 12 million gallons each month," says Randy Cable, sales manager BOC SafeQuest. "Tangible benefits to the customer include easier compliance with food safety regulations, and savings throughout the processing system as a result of reduced water use."

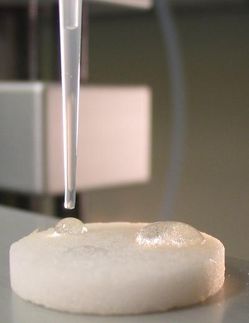

The Macron™ Loop system relies primarily on ozone for disinfecting process water. The process water is passed through a proprietary filtration system that eliminates solid contaminates as small as 25 microns. The filters also remove particulates, fats, oils, grease and foam.

Ozone is one of the world’s most powerful oxidants. It is more effective, and more environmentally friendly than chlorine and other oxidants in sterilizing water, and it kills microorganisms such as E. coli and salmonella much faster, without leaving harmful by- products. It is used to disinfect potable and bottled water as well as wastewater streams.

A recent Food and Drug Administration ruling that allows ozone for use as an anti-microbial agent in direct contact with food also enhances the performance and benefits of technologies like the Macron™ Process Water Reuse System. It allows BOC to introduce ozonated water directly onto carcasses during the washing and chilling processes to increase the technology’s anti-microbial efficacy.

The Macron™ Loop Process Water Reuse System comes complete with an on-site ozone generator and oxygen vessel for the production of ozone from oxygen, which is far simpler, more efficient and less costly than generating ozone from air.

Most read news

Topics

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.