C3 Prozess- und Analysentechnik

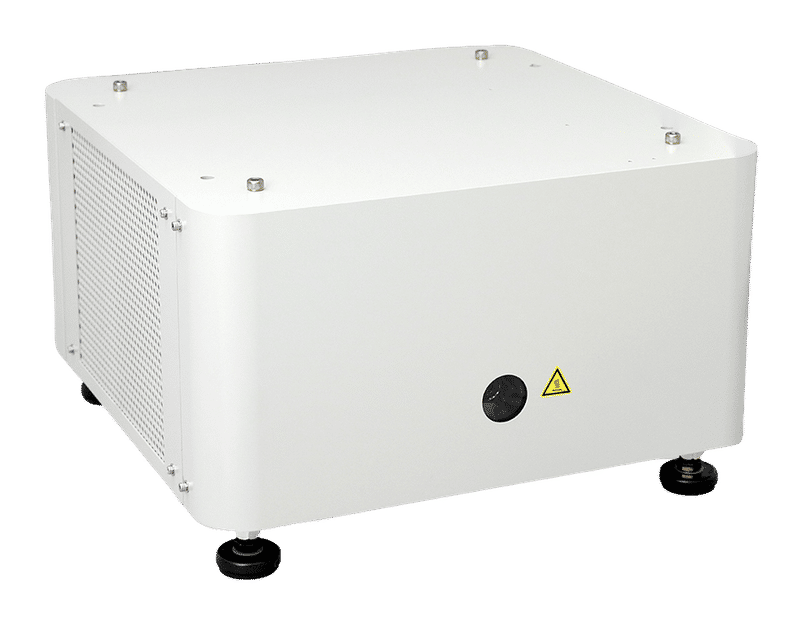

Thinky ARV-501

Mixing and Degassing in one step with vacuum support

C3 Prozess- und Analysentechnik GmbH

Reproducible - the mixing process is program-controlled and eliminates errors

Swift - typical cycle times of 5 minutes or less

Durable - mechanical gears for maximum durability and low wearout

Adhesives, Sealing Compounds, Silicones, Resins, Electrode Slurries, Paints/Varnishes, Dispersions

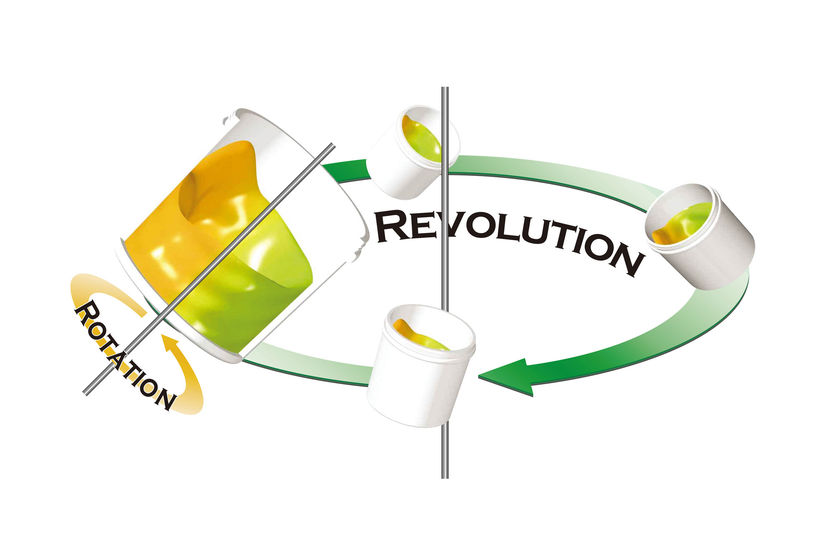

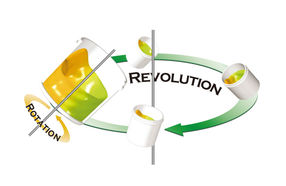

A planetary centrifugal mixer mixes and degasses a paste with other liquids or powders in an open or closed container only by movement. The revolution movement kneads and degasses the sample - if necessary supported by vacuum - the simultaneous rotation ensures circulation and thus mixing.

The THINKY ARV-501 represents a new intermediate size of non-contact vacuum planetary centrifugal mixers and is ideal for applications where the ARV-310P is too small or upscaling is desired. It uses a cup holder with mechanical counterweight adjustment for gross weights of 100-700 g. Operation is done via touch screen. 20 memory slots can be assigned with programs consisting of up to 10 steps. The standard RS232C interface allows control and/or batch reporting for quality management.

An exclusive feature is the defoaming mode - an additional transmission with increased centrifugal speed and greatly reduced self-rotation. It is particularly useful when a temperature-sensitive substance is to be degassed or low boiling substances restrict the use of vacuum.

1

Mixing and Degassing in one step - Application Example Paste

2

New THINKY mid scale Planetary Centrifugal Mixer ARV-501 with/without Vacuum

3

Application Example - Epoxy Resin

4

Optional Module - Vacuum Support

5

Principle - Mixing and Degassing without stirrer

Product classification Thinky ARV-501

Product categories

Applications

Manufacturers of similar products

Request information about Thinky ARV-501 now

Thinky ARV-501

Mixing and Degassing in one step with vacuum support