Ensuring Quality Future

Lithium-ion Batteries for Electric Vehicles

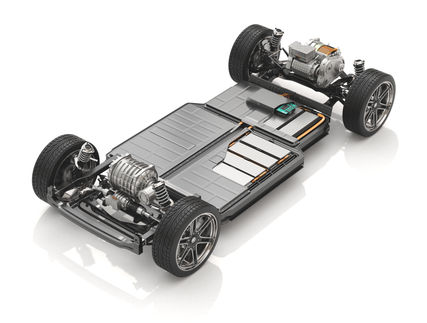

The production, sale and use of electronic vehicles is on the rise. But the technology behind electric vehicles is complex. A single EV lithium-ion battery pack contains hundreds of individual cells wired together, and a single flaw in only one of these cells can reduce performance and cause internal short circuits that could ignite a battery’s flammable electrolyte. That’s why quality control (QC) in the production of lithium-ion batteries for electric vehicles is of the utmost importance. This infographic details the three general steps for manufacturing Li-ion batteries and reviews the multiple QC checks for each step, ensuring safety throughout the entire process. Download this infographic to learn more about optical inspection, moisture analysis and precision weighing in QC testing and how Sartorius laboratory product solutions can support these.

Download white paper now

Ensuring Quality Future

Lithium-ion Batteries for Electric Vehicles

Advertisement