Green Chemistry: Sustainable p-xylene production

Green, sustainable and biodegradable polymers

Advertisement

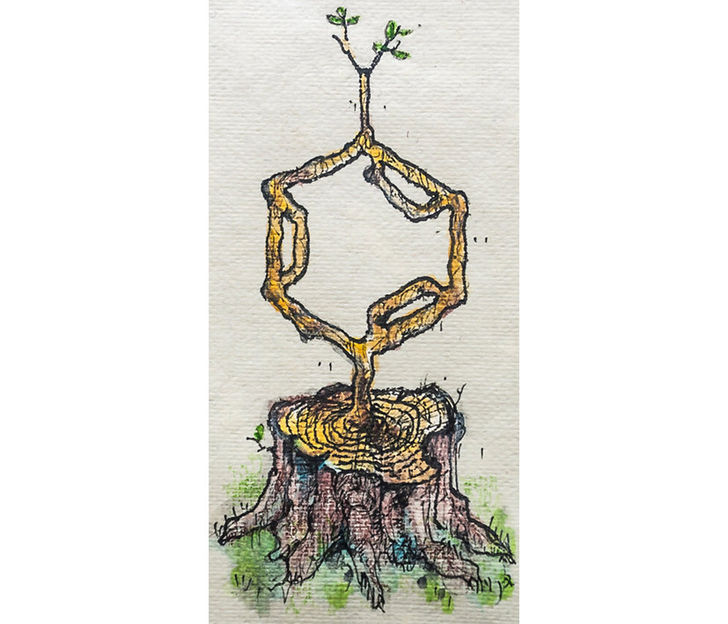

Lemonade, juice and mineral water often come in PET bottles. While these are practical and functional, their production is complex and not necessarily sustainable. The starting material for terephthalic acid, which is used to produce saturated polyesters such as PET (Polyethylene terephthalate), is p-xylene pXL. To this day, the production of pXL is still based on fossil raw materials. pXL is considered one of the most important building blocks in the polymer industry. In 2015, around 37 million tons of pXL were used, mainly for the production of PET and other polyester fibers. These figures show very clearly that there is a great need for the selective synthesis of pXL from renewable raw materials.

Synthesis of p-xylene from waste biomass and its further conversion into biopolymers.

Green Chem., 2020, DOI: 10.1039/D0GC01517B Published by The Royal Society of Chemistry

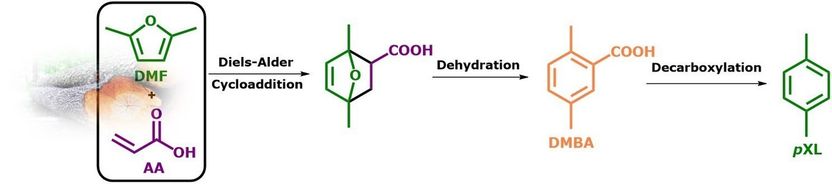

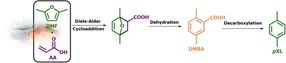

Representation of “Three-in-one” reaction in continuous flow for the synthesis of pXL from waste biomass derivable DMF and AA. J. A. M. Mesa, F. Brandi, I. Shekova, M. Antonietti and M. Al-Naji, “p-Xylene from 2,5-dimethylfuran and acrylic acid using zeolite in continuous flow system”

Green Chem., 2020, DOI: 10.1039/D0GC01517B Published by The Royal Society of Chemistry

Three-in-one heterogeneously-catalyzed reaction

The "Biorefinery and Sustainable Chemistry" team at the Max Planck Institute of Colloids and Interfaces in Potsdam has now developed a green and sustainable approach to selective pXL synthesis. This approach involves a heterogeneously catalyzed three-in-one reaction: Diels-Alder cycloaddition of biologically derived 2,5-dimethylfuran (DMF) to acrylic acid (AA), dehydration to form the phenyl ring and final decarboxylation to pXL in a continuous flow system.

Green, sustainable and biodegradable polymers

The result of this process is a very valuable product mixture. This consists of 83% pXL and 17% 2,5-dimethylbenzoic acid (DMBA), which can be easily separated due to its boiling points. This new approach will enable the synthesis of green, sustainable and biodegradable polymers in the future, for example the replacement of packaging materials for plastic bottles, films and textile fibers derived from fossil raw materials.