Simple color-changing sensor quickly identifies poisonous gases

A durable, paper-based sensor array enables quick and accurate measurements within minutes

Advertisement

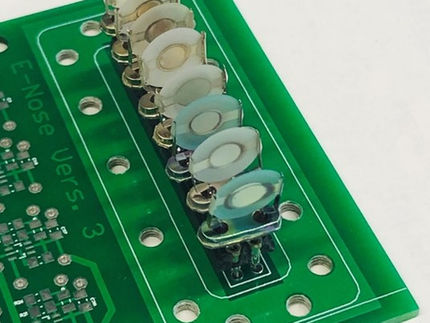

Not all poisonous gases have a smell or a color. But a tiny grid of pastel- and candy-colored squares that effectively “sniffs” out hazardous chemicals in the air such as chlorosarin — a highly toxic nerve agent — could help detect them. Researchers report in ACS Sensors that the colorful patterns in their inexpensive and durable paper-based sensor array changed in the presence of poisonous gases, allowing for quick and accurate measurements within minutes.

The tiny squares in this colorful patchwork contain silica nanoparticles that change color in the presence of toxic gases.

Adapted from ACS Sensors 2025, DOI: 10.1021/acssensors.5c01026

Electronic noses, or e-noses, are devices that detect harmful chemical vapors. But their electronic components can be pricey and aren’t practical for humid environments. Optoelectronic noses may address these limitations by replacing the electronic components with dye molecules that change color when they react with certain chemicals. Vijay Tak and his colleagues created and tested a new optoelectronic nose design: an array of sensors that detect and measure deadly gases. Each sensor within the array is a tiny paper square containing microscopic silica particles coated with dyes that change color and intensity after interacting with specific molecules or ions.

As a proof-of-concept, Tak and the research team created the sensors by soaking silica microparticles in 36 different color-changing dye solutions. After air drying them, they created a 12x3 array of color-changing sensors by placing the dried particles into a microwell plate, laying a piece of adhesive paper on top, and then flipping the plate so that the dye-containing silica particles are embossed onto the paper. To provide structural support for the array, a thin metal sheet is stuck to the sticky underside of the paper.

To test the array’s accuracy, the researchers exposed it to 12 poisonous gases at two concentrations each. The team compared photos of the squares’ color and intensity before and after five minutes of gas exposure. This produced a pattern that they could use to identify the type and concentration of gas present. In repeated experiments, the color-changing sensors achieved 99% accuracy for identifying the type of chemical threat and 96% accuracy for measuring the concentration in the gas samples. Additionally, another demonstration confirmed that the array’s accuracy was not affected by humidity.

With an estimated fabrication cost of 20 cents USD per array, the researchers say their designs could offer a cost-effective and customizable approach for environmental monitoring in real-world conditions. Next, they plan to develop a hand-held optoelectronic-nose prototype to test for hazardous chemicals outdoors.

Original publication

Rohit Shrivas, Hemant Nagpal, Sunil Agarwal, Ajeet Kumar, Raghavender Goud, Sushil Kumar Gupta, Vijay Tak; "Simple and Cost-Effective Fabrication of Embossed Colorimetric Sensor Array for an Optoelectronic Nose via Integration of a Self-Adhesive Paper and Mesoporous Colorimetric Silica Microparticles"; ACS Sensors, 2025-7-21

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.