Thin intermediate layers strengthen multilayer materials: cool satellites and flexible electronics

Advertisement

Super-light, super-flexible, super-insulating: an aluminum-coated polymer film is used to protect satellites from temperature extremes. Researchers at Empa Thun are making the material even more resistant by using a wafer-thin intermediate layer. flexible electronics and medical sensors could also be improved in this way.

Who hasn't seen the archetypal image of a satellite? Two outstretched solar "wings" and a compact body wrapped in shimmering golden or silvery foil. It is precisely this foil that researchers from the "Mechanics of materials and Nanostructures" laboratory at Empa in Thun are working on.

Its widespread use already gives it away: the foil is extremely important for satellites and space probes. It is what is known as "multilayer insulation" or superinsulation. It consists of several layers of a robust polymer with a thin metal coating - usually aluminum. On Earth, the coated film is found in the form of rescue blankets, for example.

On board the spacecraft, the super insulation protects the electronics from temperature fluctuations. "For satellites in low-Earth orbit, the temperature difference between the side facing away from the sun and the side facing the sun is around 150 degrees," says Empa researcher Barbara Putz. "However, electronics work best at a room temperature of 25 degrees Celsius." As it is directly exposed to space conditions, the super insulation itself has to be able to withstand a lot.

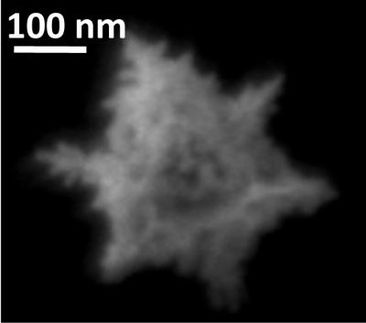

Extremely resistant polyimide is usually used as the polymer base for the thin-film structure. In addition to its temperature and vacuum resistance, this plastic is also characterized by the fact that the aluminium layer adheres particularly well to it. "The reason for this is an intermediate layer just a few nanometres thick that forms between the polymer and the aluminum during coating," explains Putz. The researcher now wants to investigate this intermediate layer in more detail - and use it in a targeted manner. The layer should not only enable better superinsulation for future satellites, but also accelerate the development of flexible electronics on Earth. In 2020, she received the Ambizione Grant from the Swiss National Science Foundation (SNSF) for this research project.

Five nanometers make all the difference

In order to gain a precise understanding of the intermediate layer and its effects on the material properties, Barbara Putz and her doctoral student Johanna Byloff opted for a simple model system: a 50-micrometre-thick polyimide film coated with 150 nanometres of aluminum. Between the metal and the plastic, the researchers applied a coating of aluminum oxide measuring just five nanometers. Working with such a thin intermediate layer is challenging. To ensure clean processing, the researchers use a coating machine from the Empa spin-off Swiss Cluster AG, which was founded in 2020 by researchers from the "Mechanics of Materials and Nanostructures" laboratory. The device makes it possible to apply several coating processes in succession to the same workpiece without removing it from the vacuum chamber.

"Our combination of materials is similar to that used for space applications, such as the European Mercury probe BepiColombo or the solar shield of NASA's James Webb Space Telescope," says Byloff. "Only there, the oxide interlayer forms naturally, whereas we produce it specifically, which allows us to adjust the properties." The space telescope's solar shield, which measures 21 by 14 meters, also illustrates the demands placed on the material in space. In addition to the large temperature differences, the insulating layers are also exposed to mechanical stresses. "On the one hand, the solar shield was stowed away when the telescope was launched and had to unfold at the deployment site without the layers tearing or separating from each other," explains Byloff. "Secondly, particles and space debris can damage the film. It is important that the damage remains localized and does not spread as long cracks over the entire surface."

From satellites to medical sensors

The researchers put their model film through its paces, subjected it to stretching tests and temperature shocks and characterized it chemically and physically. The result: the intermediate layer makes the material more elastic and significantly more resistant to tears and shear forces. Next, the researchers want to vary the thickness of the layer and apply it to other polymer substrates. "The natural intermediate layer only forms on polyimide and only in a thickness of five nanometers, which limits its usefulness," says Barbara Putz. "We expect that our artificial interlayer will enable multilayer systems on other polymers that were previously out of the question due to poor adhesion of the coating."

Satellite insulation is not the only area in which flexible multilayer systems are in demand. Putz and Byloff also see a large area of application for their research in the field of flexible electronics, which is also based on metal-coated polymer substrates. Thin-film components for electronic devices usually have several layers of different materials. But here too, the mechanical properties could be improved through the targeted use of thin intermediate layers. This could enable foldable or rollable devices, smart textiles and flexible medical sensors, for example.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Original publication

Johanna Byloff, Vivek Devulapalli, Daniele Casari, Thomas E. J. Edwards, Claus O. W. Trost, Megan J. Cordill, Shuhel Altaf Husain, Pierre‐Olivier Renault, Damien Faurie, Barbara Putz; "From Mechanics to Electronics: Influence of ALD Interlayers on the Multiaxial Electro‐Mechanical Behavior of Metal–Oxide Bilayers"; Advanced Functional Materials, 2025-11-27

Johanna Byloff, Claus Othmar Wolfgang Trost, Vivek Devulapalli, Shuhel Altaf Husain, Damien Faurie, Pierre-Olivier Renault, Thomas Edward James Edwards, Megan J. Cordill, Daniele Casari, Barbara Putz; "Atomic Layer-Deposited Interlayers for Robust Metal–Polymer Interfaces"; ACS Applied Materials & Interfaces, Volume 17, 2025-7-8

Other news from the department science

These products might interest you

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.