Neste, Borealis, Uponor, Wastewise Group enable chemical recycling of hard-to-recycle plastic waste

First production of cross-linked polyethylene (PEX) pipes based on feedstock from chemically recycled PEX waste

Advertisement

Neste, Borealis, Uponor and Wastewise have successfully produced pipes made of cross-linked polyethylene (PEX) which was based on feedstock gained from chemically recycled post-industrial waste plastic from PEX pipe production, using an ISCC PLUS certified mass-balancing approach. The partner companies believe this project is among the first implementations of chemical recycling of PEX.

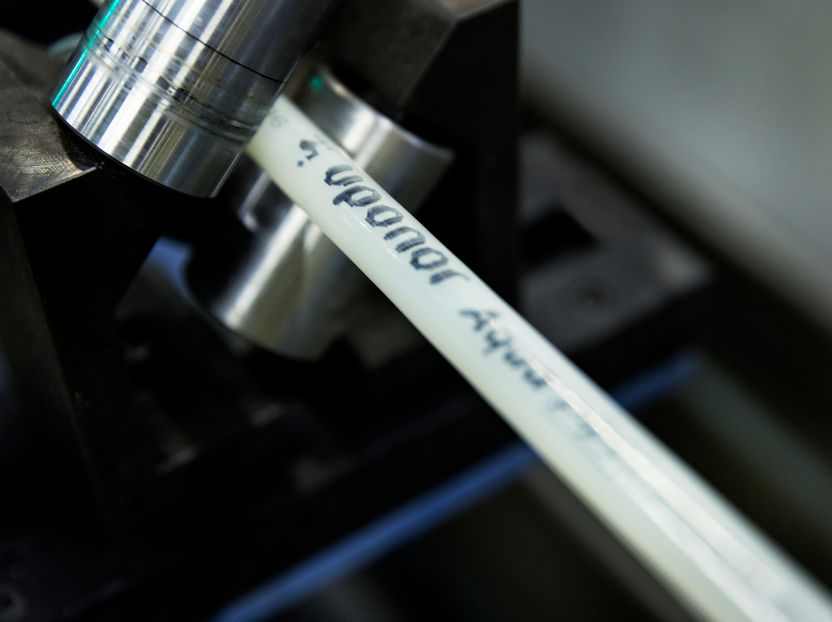

PEX pipe production at Uponor.

© Uponor

PEX pipes are an important contributor to energy efficient heating and safe plumbing due to their robustness, temperature resistance and longevity, yet the interconnected polymer chains make them nearly impossible to recycle with conventional recycling technologies. The project shows that chemical recycling can close the circularity loop for hard-to-recycle waste plastic, turning it into high-quality polymers feedstock and enabling the consecutive manufacturing of products with quality and properties identical to those in their previous life.

The cooperation sees Wastewise use their novel pyrolysis-based chemical recycling technology to liquefy industrial waste from Uponor’s PEX pipe production, breaking the polymers down back into their building blocks, which creates an oil-like recycled intermediate. This liquid is then co-processed in Neste’s oil refinery in Porvoo, Finland and upgraded into recycled Neste RETM, a high-quality drop-in feedstock for the production of new polymers. Borealis is feeding this raw material into their steam cracker and consequently polymerizing it into polyethylene as part of the company’s BorcycleTMC, chemical recycling portfolio. Finally, Uponor is using the polyethylene to create new PEX pipe systems, which can then be used in the construction sector for heating, plumbing and cooling purposes once more – eligible even for sensitive applications with high requirements, for example those used for drinking water systems. The whole value chain is traceable via ISCC PLUS certified mass-balancing.

“We are very excited about this collaboration as it gives us a head start on our transition to circular materials,” says Thomas Fuhr, Chief Technology Officer at Uponor. “PEX is by far the material that has the most versatile application uses, from building water supply systems to efficient radiant heating and cooling systems, thanks to its superior properties for the construction industry. At Uponor we have just celebrated the first 50 years of our PEX piping, and now our new long-term goal is to use 100% of our PEX waste as raw material through closed loop recycling.”

“Hard-to-recycle waste plastic as input and high-quality polymers as output are not in contradiction anymore,” says John Webster, Global Commercial Director Infrastructure at Borealis. “In fact, we are able to integrate chemically recycled PEX pipe waste plastic as a raw material into our established manufacturing processes. It doesn’t require additional tests, approvals or validation. It’s a drop-in solution ready to use even for drinking water applications.”

“The successful project demonstrates not only that recycling of PEX is possible via chemical recycling, but it also shows that it’s actually possible with high yields: some 80% of the PEX production waste can be added back to the circle,” says Kaisa Suvilampi, Managing Director and Partner at Wastewise. “Through our processes, we were able to turn PEX into pyrolysis oil of sufficient quality to use it as input for a refinery, which in turn can process it into a high quality cracker feed. This project strikes certain PEX off from the list of materials giving recyclers a headache.”

“The curtain is opening for chemical recycling,” added Mercedes Alonso, Executive Vice President Renewable Polymers and Chemicals at Neste. “It will still take time to reach large-scale operations, but this project is providing the blueprint for circular value chains for polymers via chemically recycling. It’s pushing the technology from the promise to the delivery phase. Further, it shows the importance of bringing the right partners together to cooperate.”

Due to the involved parties’ commitment to pushing circular solutions for polymers and the solution’s drop-in character, the partners were able to establish the value chain in a rather short period of time. Little more than six months passed between the start of the project and the production of the first pipes made with chemically recycled PEX waste.

The partnership holds potential for further cooperation beyond production waste: The PEX pipes made by Uponor have already been optimized from a resource efficiency point of view by reducing their wall thickness and increasing lifetime. At the end of their long life, mechanical recycling is so far the first recycling option, but it also means downcycling the materials, e.g. into other construction materials or items such as hockey sticks. With chemical recycling, though, the PEX waste pipes can be turned into fully functional PEX pipes again. Moving forward, the partners will evaluate further opportunities for cooperation. Aside from broadening the waste material pool, this may also include higher recycled volumes.