Metal nonwovens: material for the batteries of the future

Start-up commercializes nonwoven electrodes: "With our technology, we have the chance to catch up with Asian manufacturers and be better"

Advertisement

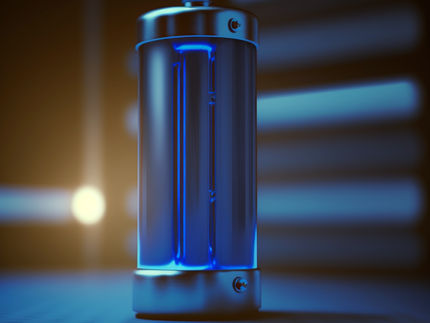

batteries are becoming ever more powerful. A discovery by researchers at the Max Planck Institute for Medical Research in Heidelberg could now give them a significant energy boost. A team led by Max Planck Director Joachim Spatz has discovered that metal fleece as a contact material in battery electrodes significantly accelerates the charge transport of metal ions in particular. This makes it possible to build significantly thicker electrodes than is usual today. This means that a good half of the contact metal and other materials that do not contribute to energy storage can be saved. In this way, the researchers can significantly increase the energy density in batteries.

The status quo: a compromise between energy density and performance

"The basis for this is a previously unknown mechanism that we discovered during ion transport in electrodes," says Joachim Spatz. Battery electrodes consist of a contact material and an active material. The contact material - which today is a copper foil for the negative terminal of lithium-ion batteries and an aluminum foil for the positive terminal - only has the task of transporting the current to and from the electrode. The active material is the actual storage material that absorbs and releases the charge during charging and discharging. Battery manufacturers now use graphite in the negative terminal and various lithium-containing inorganic compounds in the positive terminal. The active material is porous so that it is penetrated by the liquid electrolyte.

Although the active materials commonly used today absorb quite a lot of charge, they conduct ions very poorly. The ions have to migrate through the liquid electrolyte into the active material. Because they are packed into a shell of electrolyte molecules and are correspondingly voluminous, they only move slowly through the electrolyte. And they do not move well in the active material itself. This presents battery manufacturers with a dilemma: either they make the electrodes thick so that their energy density is as high as possible - but then the batteries in question cannot be charged and discharged quickly. Or they make the electrodes extremely thin and accept that the energy density drops in order to achieve rapid charging and discharging. With a compromise between the two properties, battery manufacturers today end up with electrodes that are around a tenth of a millimeter thin. This is roughly equivalent to the diameter of a human hair.

A new approach: accelerated ion transport through an electrical double layer

In a study published in the specialist journal ACS Nano, the Heidelberg team has now shown a way of producing electrodes that are at least ten times thicker than is usual today and can still be charged and discharged quickly. The researchers have shown that lithium ions strip off their molecular shell on a copper surface, deposit there and form an electrical double layer, the so-called Helmholtz layer, with electrons that accumulate under the metal surface. "Using a specially developed measurement setup and theoretical calculations, we have shown that the lithium ions move through the Helmholtz layer around 56 times faster than through the electrolyte," says Joachim Spatz. "Metal surfaces are therefore a kind of highway for the metal ions."

If metal ions move so quickly across metal surfaces, this means that it makes sense to criss-cross the active material with a metallic highway network for ion transport. This is exactly what Joachim Spatz and his team have done. The researchers produced nonwovens from metal threads that are only a few hundredths of a millimeter thick. They then inserted the active material into the metal nonwovens. This allowed them to use only half as much copper as is needed for conventional foil electrodes. Even if an electrode is around ten times thicker than is usual today, the lithium ions still flow into and out of the active material via a fleece so quickly that it is sufficient for use in electric cars, for example. The bottom line is that the energy density of the nonwoven electrodes is up to 85 percent higher than that of film electrodes.

Batene GmbH: a start-up for nonwoven electrodes

"Supplying a material with charge via two-dimensional layers is in no way efficient," says Joachim Spatz, pointing to the example of nature: it supplies organisms via a three-dimensional network of vessels. "That is the goal of our technology: a 3D supply network for charge carriers that can be used to charge and discharge batteries efficiently."

The nonwoven electrodes are not only significantly more efficient than film electrodes, they are also easier and cheaper to produce. This is because in the production of today's batteries, manufacturers have to apply the thin layers of active material to the contact foils in a complex process, sometimes using toxic solvents. In contrast, the active material can be applied to the nonwovens in powder form. "With dry filling, we can probably save 30 to 40 percent of the production costs and the production facilities need a third less space," says Joachim Spatz.

As the researcher sees great potential in the nonwoven electrodes, he has already founded a start-up that is developing the battery technology to market maturity together with major car manufacturers, for example. And this, Joachim Spatz is convinced, could also improve the competitive chances of German manufacturers in the rapidly developing battery technology: "With our technology, we have the chance to catch up with Asian manufacturers and be better."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Original publication

Other news from the department science

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.