From waste product to raw material - manufacturing quality polymer materials based on CO2

German Federal Ministry of Education and Research provides funding of more than EUR 4.5 million for “Dream Production“

Advertisement

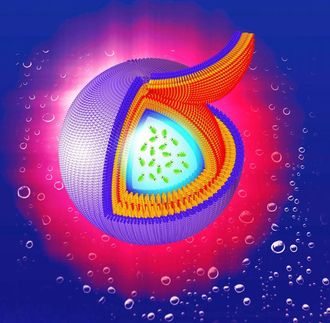

Researchers from Bayer MaterialScience and Bayer Technology Services are working together with RWE Power AG and academic partner RWTH Aachen University on the sustainable use of carbon dioxide (CO2). At the heart of what has been called the “Dream Production” project, sits the construction and commissioning of a pilot plant at Chempark Leverkusen. This is to be the location for the kilogram-scale production of polyether polycarbonate polyols (PPPs) that will be processed into polyurethanes and will involve the chemical bonding of CO2, which will be an integral raw material in this sustainable process. The key technology for this is catalysis.

While catalysis is currently used in the manufacture of more than 85 percent of all chemical products, the low energy density of carbon dioxide has hindered the application of this technology in any attempt to put CO2 to practical use.

But in recent laboratory tests, 'dream reactions' have been achieved; i.e. reactions created in a laboratory but the industrial application of which have yet to be proven; resulting in the process being described as a 'dream', for the time being.

For the first time, these promising results will be transferred from the laboratory to a larger scale in the 'Dream Production' project. During the next three years the German Federal Ministry of Education and Research (BMBF) will invest a total of more than EUR 4.5 million in the initative, the project supervision of which is the German Aerospace Center (DLR).

Polyether polycarbonate polyols (PPP) produced using catalysis are extremely attractive materials. As well as the incorporating CO2 in the process, there are also further interesting possibilities involving there use in polyurethane chemistry. “Using the waste product CO2 to manufacture versatile materials is an amazing achievement made possible by catalysis – and one which both we and our project partners are very proud of,” said Patrick Thomas, Chief Executive Officer of Bayer MaterialScience AG. “What’s more, as an ultra-efficient organic insulating material, polyurethanes save around 80 times more energy during their service life than is required for their production. This ensures that PPPs have a doubly positive effect on climate protection.”

As well as being used for building insulation, lightweight polyurethane components also help to reduce weight in the automotive industry, for example, resulting in significant energy savings. However, polyurethanes are also part of everyday life when used as a material for manufacturing high-quality mattresses and upholstered furniture.

“Dream Production” is based on a forerunner project “Dream Reactions”, which was initiated by Bayer Technology Services and also funded by the BMBF. “As part of this project, we dealt with fundamental questions focusing on harnessing CO2 by using newly developed catalysts. We have achieved promising results that form the basis for industrial implementation in the Dream Production project,” explains Dr. Dirk Van Meirvenne, managing director of Bayer Technology Services GmbH.

Using CO2 as a raw material for manufacturing polymers helps cut consumption of conventional raw materials and therefore fossil fuels. This strategy also shows future generations how to make sustainable use of natural resources.

The CO2 used for the project will come from RWE Power's lignite-fired power plant at Niederaußem. This is where the electricity generator operates a CO2 scrubbing system at its coal innovation centre, by which the carbon dioxide is captured from the flue gas. For the Dream Productions project the CO2 scrubber will be equipped with an additional liquefaction system so that the carbon dioxide can be transported to Leverkusen. The CO2 liquefaction system will be designed and operated with flexibility to meet various CO2 pressures and purities on a scale ranging from kilograms up to tonnes.