Whispering light hears liquids talk

University of Illinois researchers build first-ever bridge between optomechanics and microfluidics

Advertisement

Ever been to a whispering gallery—a quiet, circular space underneath an old cathedral dome that captures and amplifies sounds as quiet as a whisper? Researchers at the University of Illinois at Urbana-Champaign are applying similar principles in the development optomechanical sensors that will help unlock vibrational secrets of chemical and biological samples at the nanoscale.

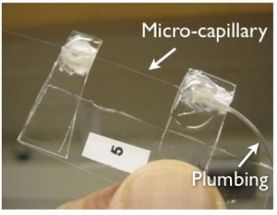

This image shows a microfluidic optomechanical capillary resonator with fluid control tubing.

Gaurav Bahl, University of Illinois

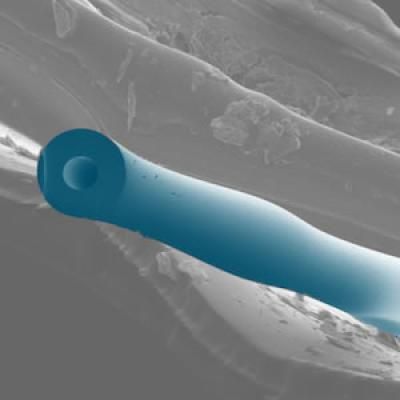

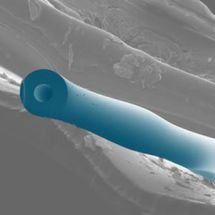

This is a false-color SEM (scanning electron micrograph) of the microfluidic optomechanical resonator.

Gaurav Bahl, University of Illinois

"Optomechanics is an area of research in which extremely minute forces exerted by light (for example: radiation pressure, gradient force, electrostriction) are used to generate and control high-frequency mechanical vibrations of microscale and nanoscale devices," explained Gaurav Bahl, an assistant professor of mechanical science and engineering at Illinois.

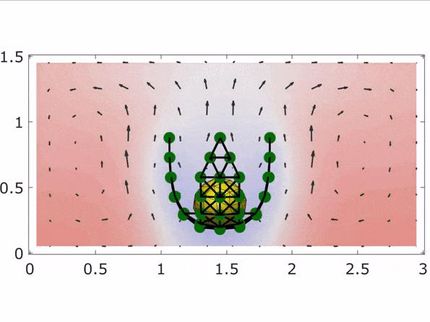

In glass microcavities that function as optical whispering galleries, according to Bahl, these miniscule optical forces can be enhanced by many orders-of-magnitude, which enables 'conversations' between light (photons) and vibration (phonons). These devices are of interest to condensed matter physics as the strong phonon-photon coupling enables experiments targeting quantum information storage (i.e. qubits), quantum-mechanical ground state (i.e. optomechanical cooling), and ultra-sensitive force measurements past the standard quantum limit.

Researchers developed a hollow optomechanical device made of fused silica glass, through which fluids and gases could flow. Employing a unique optomechanical interaction called Brillouin Optomechanics (described previously in Bahl et al, Nature Communications 2:403, 2011; Bahl et al, Nature Physics, vol.8, no.3, 2012), the researchers achieved the optical excitation of mechanical whispering-gallery modes at a phenomenal range of frequencies spanning from 2 MHz to 11,000 MHz.

"These mechanical vibrations can, in turn, 'talk' to liquids within the hollow device and provide optical readout of the mechanical properties," said Bahl, who is first author of the paper, "Brillouin cavity optomechanics with microfluidic devices," published in Nature Communications.

By confining various liquids inside a hollow microfluidic optomechanical (μFOM) resonator, researchers built the first-ever bridge between optomechanics and microfluidics.

"We found that the optomechanical interaction in the μFOM device is dependent on the fluid contained within," Bahl said. "These results are a step towards novel experiments probing optomechanics on non-solid phases of matter. In particular, the high frequency, high quality-factor mechanical vibrations demonstrated in this work may enable strongly localized, high-sensitivity, optomechanical interaction with chemical and biological samples."

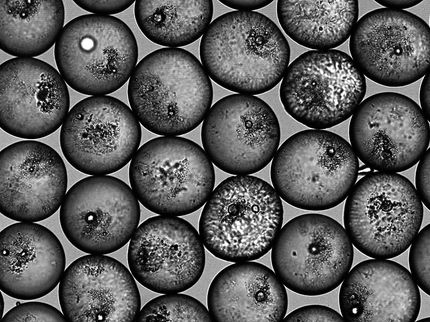

Potential uses for this technology include optomechanical biosensors that can measure various optical and mechanical properties of a single cell, ultra-high-frequency analysis of fluids, and the optical control of fluid flow.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.