Ticona Breaks Ground for 30,000 Ton Plant for GUR® Ultra-High Molecular Weight Polyethylene in Bishop, Texas

Advertisement

Ticona broke ground today for a 30,000 metric tons/year (approx. 60 million lbs/year), € 50-million plant to manufacture GUR® ultra-high molecular weight polyethylene (UHMW-PE) in Bishop, Texas. The new plant, which is scheduled to begin operation in the 3rd quarter of 2002, will double the company's GUR capacity in North America and replace its existing UHMW-PE plant in Bayport, Texas.

Ticona, the world's leading producer of UHMW-PE, also operates a GUR plant in Oberhausen, Germany. When the new plant is completed, the company's total GUR capacity will be about 60,000 metric tons/year (approx. 120 million lbs/year).

Bob Engle, Ticona's Global GUR Business Director, said, "This new plant will meet growing market demand for GUR and further improve our manufacturing efficiencies and product quality."

Ticona Chief Operating Officer Stefan Sommer added, "The Bishop Plant has been part of the Celanese family for over 50 years, and its high standards for product quality, operational efficiency, and commitment to protecting the environment serve as a role model for our other plants - in the U.S. and around the globe."

"With the GUR addition," Sommer said, "the Bishop Plant soon will produce two of the three engineering thermoplastics where Ticona holds market leadership positions." In addition to GUR® UHMW-PE, the other market-leading product made at Bishop is Celcon® acetal copolymer. Ticona produces its market-leading Vectra® liquid crystal polymer (LCP) in Shelby, NC.

The Bishop Plant also produces Ticona's Celanese® Nylon-6/6 engineering thermoplastic and various acetate products for Celanese, Ticona's parent. It is one of the largest manufacturing sites for Ticona and Celanese.

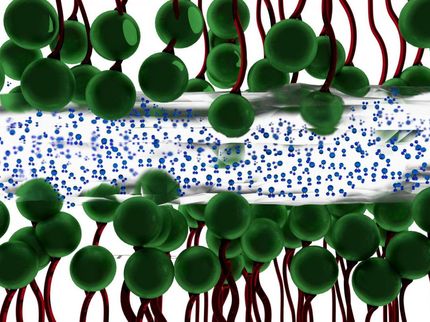

GUR UHMW-PE has an extremely low coefficient of friction and provides outstanding abrasion resistance and toughness. It is often used in demanding material handling applications in bottling machines, papermaking equipment, chemicals and other process industries. Typical GUR applications include bulk containers, truck linings, conveyor chain guides, marine dock fenders, automotive battery separators, pump housings, and ski and snowboard bottoms. GUR is also used to produce porous products for writing instruments, air and water filters for industrial and residential use, and wear resistant and texturing additives for thermoplastics and elastomers.