Ticona Introduces UHMW-PE MicroPowder Grades As Functional Additives for Paints, Plastics, Rubbers and Sealants

Advertisement

Ticona has introduced its GUR® MicroPowder ultra-high molecular weight polyethylene (UHMW-PE) line for use as performance additives in paints, coatings, plastics, rubbers, sealants and other materials, as well as in wicking and filtration applications. These extremely fine powder products of UHMW-PE, have average particle sizes ranging from 30 to 60 microns.

GUR® MicroPowder grades enhance abrasion and mar resistance, coefficient of friction (COF), chemical resistance, impact strength and other mechanical properties. Benefits in specific applications include:

• In paint and coatings: Improved surface texture, wear resistance and gloss reduction.

• In rubber: Low COF and improved thermal properties, impact strength and abrasion resistance.

• In plastics: Better slip, abrasion resistance and texture.

• In sealants and polishing compounds: Lower cohesive forces.

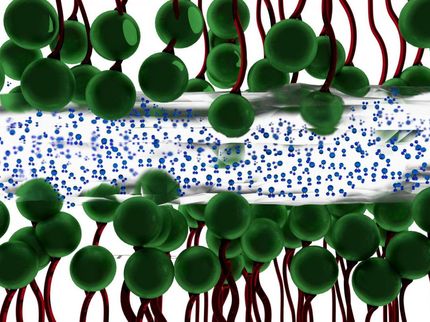

• In micro-filters: Low pressure drop with fine porosity and improved mechanical properties.

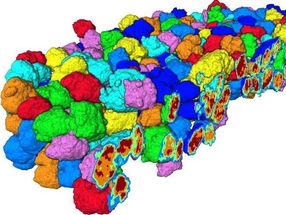

GUR® MicroPowder with an average particle size of 30 microns, has a specially engineered particle morphology which creates a unique light scattering effect when used as a matting agent in coatings. The 60-micron, GUR® MicroPowder grade has smooth, relatively spherical shaped particles. Both grades disperse and bond well in many matrices.

GUR® MicroPowders need no additional micronizing processing before use as do most thermoplastic additives, which are sold as pellets and must first be ground and sieved to size. The GUR® powders can be dispersed with standard mixing equipment, usually at concentrations of 3 to 10 wt.%. They also withstand high-intensity mixing with minimum particle deformation.

The GUR® powders are similar to fluoropolymer powder additives in that they reduce COF and improve chemical resistance, but they offer better surface protection than fluoropolymer, e.g., less surface abrasion loss and higher scratch resistance. GUR® MicroPowder grades do not absorb moisture, have a melting temperature of about 135°C, and an effective thermal range of -265° to 90°C. They also have extended deformation resistance under low mechanical load, even above their melting point, which can be important in such applications as filters for hot liquids and coatings cured at high-temperature.

In addition to the standard GUR® MicroPowder grades, GUR® fines can be classified to provide specific particle size cuts. Ticona is capable of tailoring particle shapes and molecular weights from 5 to 10.5 million g/mol for GUR® MicroPowder.