NEC Develops New Bioplastic That Realizes Higher Heat Conductivity Than Stainless Steel

Advertisement

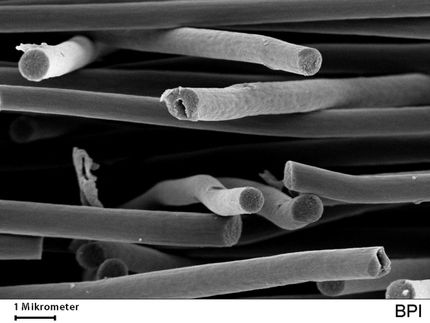

NEC Corporation has developed a completely new kind of bioplastic composed of plant-based material and carbon fiber, which realizes heat conductivity higher than that of stainless steel, according to the company. The bioplastic is expected to make electronic products more environmentally sound, while solving conventional heat release issues.

The features of the new bioplastic are as follows.

1) Creation of a cross-linked structure of carbon fiber through use of a unique binder in the polylactic acid (PLA)*1 resin achieves high heat diffusion (with carbon fiber of 10% and 30% the heat diffusion ability of the new bioplastic composite is comparable to and double that of stainless steel respectively). This enables good heat conductivity in the plane direction of the PLA resin board, which is a characteristic conventionally difficult to attain in metal boards.

2) The composite is extremely environmentally friendly as it is mainly composed of biomass-based components including the binder (the biomass ratio exceeds 90%, excluding inorganic components such as the carbon fiber).

3) The strength and moldability of the composite have been fundamentally verified for use in electronic products.

NEC will continue to develop these technologies toward realization of mass production of the bioplastic composite by the end of the fiscal year ending March, 2009, after which it will start to use the composite in housings of electronic products and seek out new applications.

Most read news

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.