Flexible Catalytic Oxidation System handles extremes of Russian weather

Advertisement

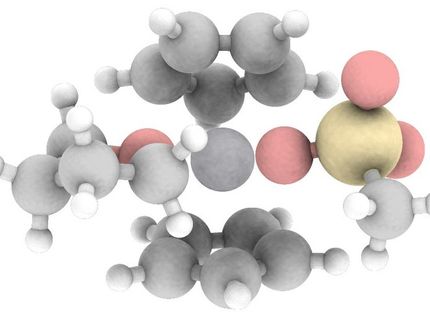

AirProtekt has supplied a Honeycat Catalytic Oxidation System to a Medium density Fibre board (MDF) processing plant in Russia. AirProtekt optimised the Honeycat system for the abatement of phenol, formaldehyde and Methanol vapours given off during the industrial resin manufacturing stage of the Russian plant’s MDF production process.

The complete catalytic oxidation equipment was built, tested and fresh air commissioned in the UK inside a dedicated ISO container before being shipped to the Russian site located near the Ural Mountains where the abatement equipment was connected to the process plant. The catalytic oxidation system, which incorporates gas tight sealing to prevent localised emissions of formaldehydes, also features high efficiency ceramic insulation/fibre mats that are designed to significantly reduce heat losses and external surfaces temperatures.

The low process flowrates featured at the Russian MDF processing plant allow a compact oxidiser design to be used which can be built inside a standard ISO container complete with control and air conditioning systems. The ISO container-based system enables the equipment to be provided as an almost mobile application solution that can be easily moved from site to site. The solution has the added benefit of helping to minimise system running costs. AirProtekt has supplied a very low maintenance electrically pre heated system that features low catalyst operating temperatures that result in low thermal stress solution that extends operating life.

“The Honeycat Air Pollution Control System was designed to withstand operation in very extreme ambient conditions that are faced in Russia. The system is capable of running at -50°C in the winter and +30°C in the summer. The new unit is the third Honeycat Catalytic Oxidation System supplied by AirProtekt to the Russians in recent years,” explained Trevor Lawton, AirProtekt’s managing director.

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.