Process measurement technology:

OPUS

In- and On-Line Particle Size Distribution Analysis in Highly Concentrated Suspensions and Emulsions

Real-time measurement in the process environment | simple installation | low-maintenance operation

Measuring without dilution | optimal use with optically dense liquids

Use in process, laboratory as well as product and process development | grinding, crystallisation

Particle size analysis with ultrasonic extinction from <0.1 - 3,000 µm in real time

Ultrasonic extinction provides an outstanding performance for in-line and on-line particle size analysis of suspensions and emulsions. One of the major benefits is the ability to operate in highly concentrated mediums, which typically come along with wet process stages. A solid content between 5 and 50 % by volume is a typical range of concentration. These are perfect conditions for OPUS, which even may be applied at concentrations up to 70 % by volume – typical for paste-like particulate systems. Using sound waves instead of light waves, analysis of suspensions or emulsions is independent of transparency and may be conducted in totally opaque disperse matter like water droplets in crude oil, mineral slurries or even carbon particles in liquid pitch. Paints, sugar pastes or pharmaceutical suspension also belong to the main field of application. Ultrasonic extinction allows for a rugged and robust probe design that resists typical process conditions such as high temperatures, pressures or aggressive media and abrasive materials.

Specifications

1

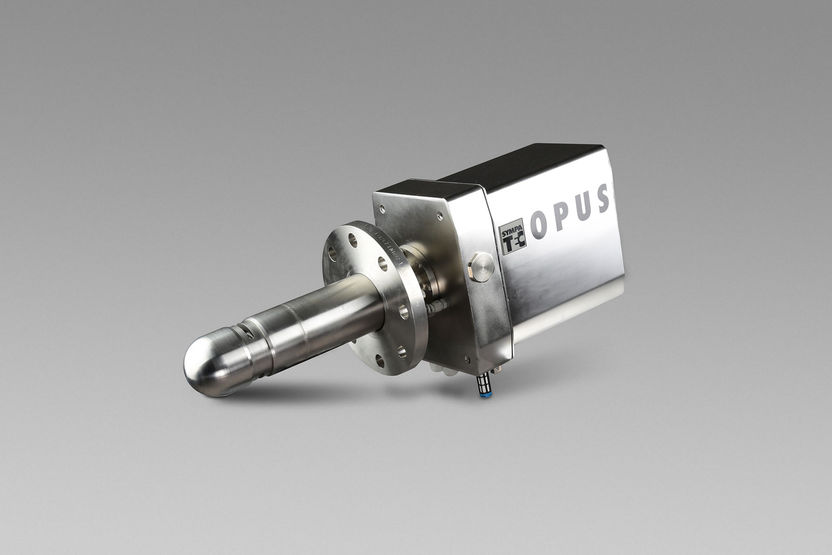

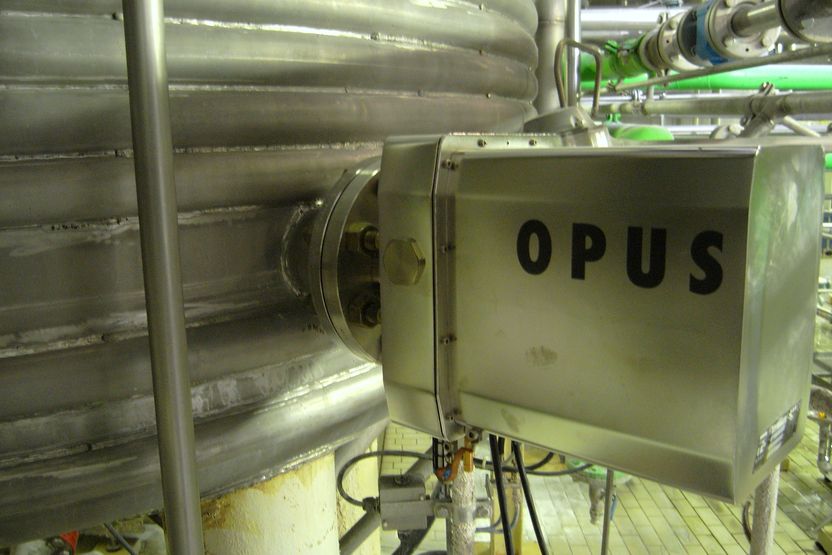

OPUS | Process-proven method for particle size analysis

2

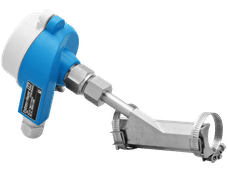

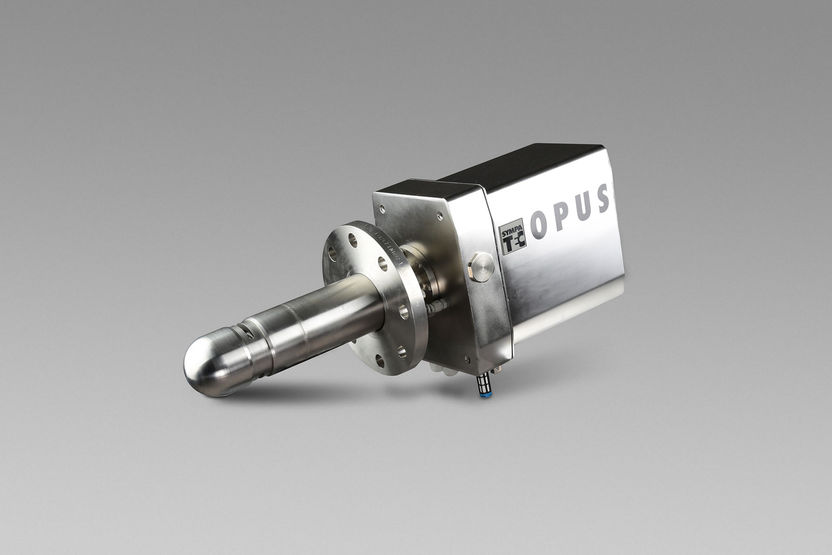

OPUS/FT with flowthrough adapter installed in main product stream for pipes ranging from DN10 to DN25 with standby rack

3

OPUS/BP with bypass adapter in process pipes DN50 and flow rates up to 10,000 l/h

4

OPUS/AF monitors changes in particle size distribution and concentration in continuous real-time analyses

5

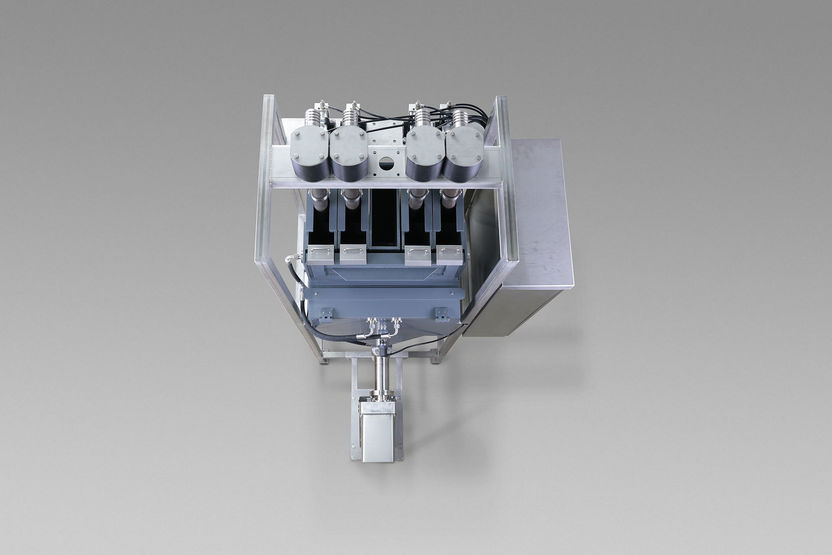

OPUS/FT with MULTIPLEXER for particle characterisation of solids-laden product streams up to four process lines

Request information about OPUS now

Process measurement technology: OPUS

In- and On-Line Particle Size Distribution Analysis in Highly Concentrated Suspensions and Emulsions

Product classification OPUS

Product categories

Applications

Manufacturers of similar products

Advertisement

Find more process measurement technology and related products

Find OPUS and related products in the theme worlds

Topic World Particle Analysis

Particle analysis methods allow us to study tiny particles in various materials and reveal their properties. Whether in environmental monitoring, nanotechnology or the pharmaceutical industry, particle analysis gives us a glimpse into a hidden world where we can decipher the composition, size and shape of particles. Experience the fascinating world of particle analysis!

Topic World Particle Analysis

Particle analysis methods allow us to study tiny particles in various materials and reveal their properties. Whether in environmental monitoring, nanotechnology or the pharmaceutical industry, particle analysis gives us a glimpse into a hidden world where we can decipher the composition, size and shape of particles. Experience the fascinating world of particle analysis!