To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

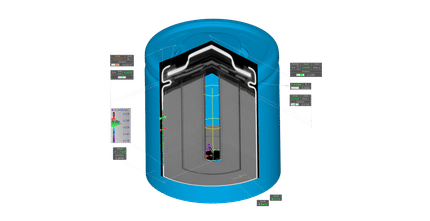

Electron backscatter diffractionElectron backscatter diffraction (EBSD), also known as backscatter Kikuchi diffraction (BKD) is a microstructural-crystallographic technique used to elucidate the crystallographic texture or preferred orientation of any crystalline or polycrystalline materials. EBSD can be used to index and identify the seven crystal systems, and as such it is applied to crystal orientation mapping, defect studies, phase identification, grain boundary and morphology studies, regional heterogeneity investigations, material discrimination, and using complimentary techniques, physico-chemical identification. Traditionally these types of studies have been carried out using x-ray diffraction (XRD), neutron diffraction and/or electron diffraction. Experimentally EBSD is conducted using a scanning electron microscope (SEM) equipped with a backscatter diffraction camera. The diffraction camera is essentially a focal plane CCD coupled with a phosphor screen, which is inserted into the specimen chamber of the SEM at an angle greater than or equal to 90° to the pole piece. A flat/polished crystalline specimen is placed into the normal position in the specimen chamber, but is highly tilted (~70° from horizontal) towards the diffraction camera. When the electrons impinge on the specimen they interact with the atomic lattice planes of the crystalline structures, many of these interactions satisfy Bragg conditions and undergo backscatter diffraction. Due to the angle of the specimen these diffracted electrons are directed towards and impinge upon the phosphor screen of the diffraction camera causing it to fluoresce, this fluorescent light is then detected by the CCD. The diffracted electrons form an image termed a diffraction pattern on the diffraction camera. This pattern is unique to the microstructural-crystallographic properties of the material. And using computer aided interpretation can reveal a multitude of information. Each diffraction pattern will show several intersecting lines termed Kikuchi bands, these correspond to each of the lattice diffracting planes and can be indexed individually by the Miller indices of the diffracting plane which formed it. Product highlight

IndexingThe first step in the EBSD process after pattern collection, described above, is indexing. This allows for identification of the microstructure or orientation at the single point on the sample from where the pattern was collected. With EBSD software, pattern bands are detected via a mathematical routine called the Hough transform in which every pixel denotes a unique line in the EBSD pattern. Because angles between bands represent angles between lattice planes, when the position / angles between three bands are known an orientation solution can be determined. A common standard for determining orientation from pattern bands is a triplet voting scheme. With this routine, the system will automatically calculate all orientations for all possible three band combinations (triplets) and count the number of votes for each candidate orientation. One orientation will have the highest number of votes and this is typically the correct solution. This method works very well for deformed materials and at overlapping patterns where triplets belonging to the stronger pattern determine the orientation solution. It can also be used as a basis for confidence index which is a measure of the difference in votes between the best and second best orientation solution (how well the solution matches). An alternate routine is to start with all possibilities from three bands and converge to a single solution by adding bands as needed. Orientation MappingA further function of EBSD is mapping of information collected from a prescribed grid of points on the sample. A sample area is designated and collection parameters selected. The system will then automatically raster the electron beam accordingly, and at each point the indexed orientation information is stored into a dataset. From this dataset numerous maps, charts and plots can be generated [1] . Some of these include grain orientation maps, grain boundary maps, image quality maps, grain size charts, misorientation charts and texture plots. Integrated EBSD/EDS MappingWhen simultaneous EDS/EBSD collection can be achieved, the capabilities of both techniques can be enhanced. There are applications where sample chemistry or phase cannot be differentiated via EDS alone because of similar composition; and structure cannot be solved with EBSD alone because of ambiguous structure solutions. To accomplish integrated mapping, analysis area is scanned and at each point Hough peaks and EDS region-of-interest counts are stored. Positions of phases are determined in X-ray maps and measured EDS intensities are given in charts for each element. For each phase the chemical intensity ranges are set to select the grains. All patterns are then re-indexed off-line. The recorded chemistry determines which phase / crystal structure file is used for indexing of each point. Each pattern is indexed by only one phase and maps displaying clearly distinguished phases are generated. EBSD when used together with other in-SEM techniques such as cathodoluminescence (CL), wavelength dispersive X-ray spectroscopy (WDS) and/or energy dispersive X-ray spectroscopy (EDS) can provide a deeper insight into the specimen's properties. For example, the minerals calcite (limestone) and aragonite (shell) have the same chemical composition - calcium carbonate (CaCO3) therefore EDS/WDS cannot tell them apart, but they have different microcrystalline structures so EBSD can differentiate between them. See alsoCategories: Diffraction | Spectroscopy |

|

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Electron_backscatter_diffraction". A list of authors is available in Wikipedia. |