Hot Wheels: World Market for Styrene-Butadiene Rubber Analyzed

Advertisement

Styrene-butadiene rubber (SBR) is the best-selling synthetic rubber and for decades, has been indispensable for many applications. In everyday life, SBR is mainly found in vehicle tires. According to a recent market study by Ceresana, worldwide consumption for this elastomer type amounts to about 5.1 million tonnes. More than half of global demand is generated in the region Asia-Pacific. Analysts at Ceresana expect global market volume of SBR to increase by 2.0% p.a. until 2025.

Butadiene and Styrene

Styrene-butadiene rubber is a copolymer consisting of the chemicals butadiene and styrene. SBR is produced by emulsion polymerization (E-SBR) or by solution polymerization (S-SBR). E-SBR is accounting for about 72% of total demand. The smaller S-SBR market, however, is accounting for much more dynamic growth rates of 3.8% per year.

Tires Are the Most Important Application

The most important sales market for SBR in 2017 was the segment tires: More than 67% of total worldwide demand was generated by tires and replacement tires. Tires are mainly made of SBR, butadiene rubber, and natural rubber. E-SBR is mostly used for standard tires. In contrast, S-SBR is needed to manufacture tires with high abrasion resistance and low rolling friction.

Growing Demand for SBR

The manufacture of industrial products is the second largest application area worldwide, consuming about 740,000 tonnes. From the chemical industry to mechanical engineering to the electrical and electronics industry, SBR is required for a wide range of applications, such as conveyor belts, roll covers, hoses, profiles, seals, cables, adhesives, moldings, and the modification of plastics. In the construction industry, SBR is also used for pipes, roofing films, and for the modification of other building materials. SBR is also needed for numerous sports and consumer goods.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

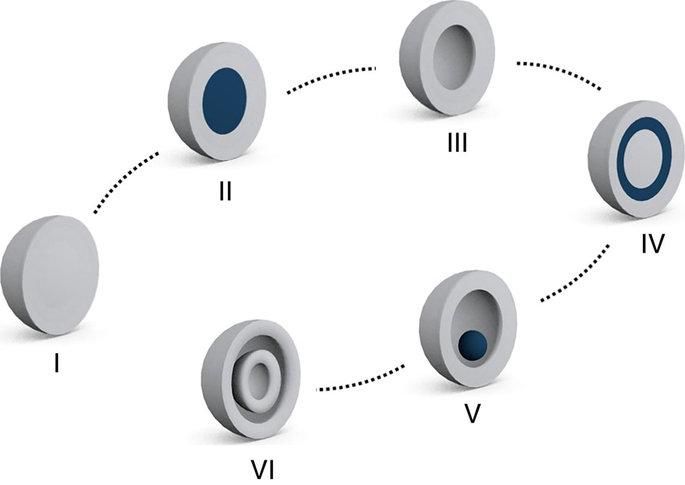

New insights into the forms of metal-organic frameworks

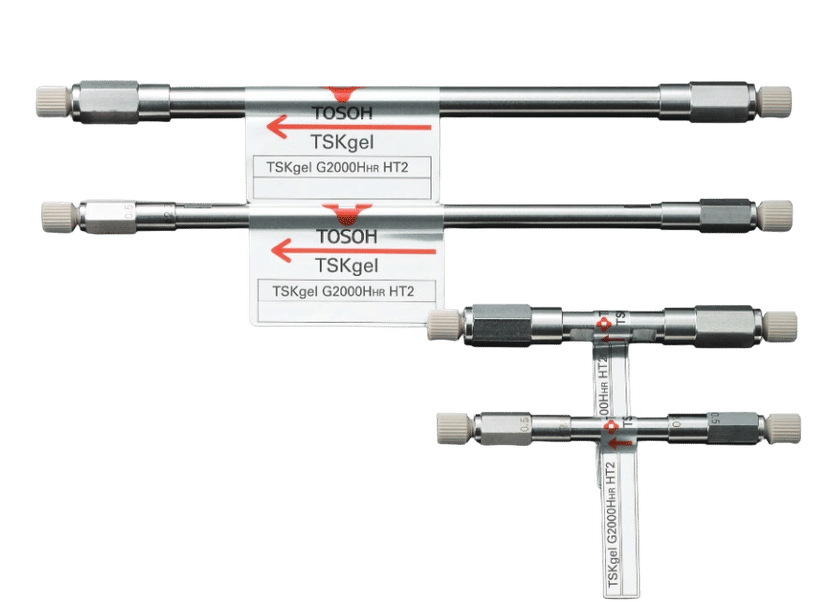

TSKgel HT2 Series Columns | GPC columns | Tosoh

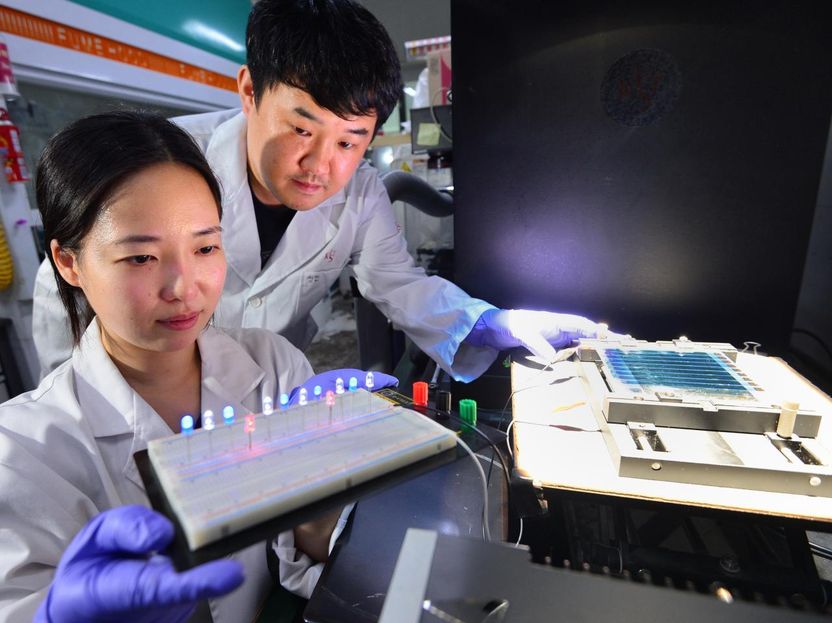

Development of photovoltaics that can be applied like paint for real-life application - Future application as plastic-based photovoltaic paint technology

The weight of pollution: exposure linked to obesity - Chronic exposure to environmental pollutants found to increase risk of cardiovascular disease