Wireless device makes clean fuel from sunlight, CO₂ and water

Significant step toward achieving artificial photosynthesis

Advertisement

Researchers have developed a standalone device that converts sunlight, carbon dioxide and water into a carbon-neutral fuel, without requiring any additional components or electricity.

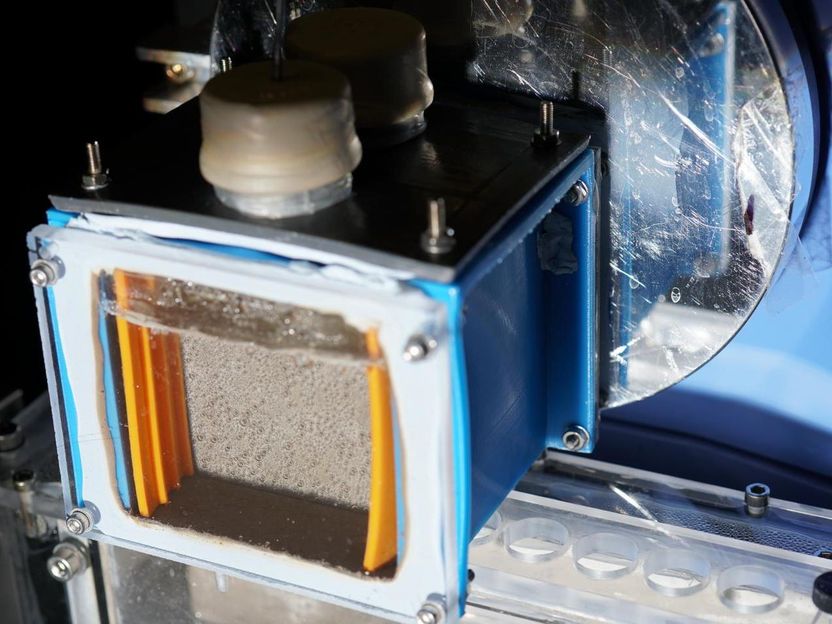

This device, developed by a team from the University of Cambridge, is a significant step toward achieving artificial photosynthesis - a process mimicking the ability of plants to convert sunlight into energy. It is based on an advanced 'photosheet' technology and converts sunlight, carbon dioxide and water into oxygen and formic acid - a storable fuel that can be either be used directly or be converted into hydrogen.

University of Cambridge

The device, developed by a team from the University of Cambridge, is a significant step toward achieving artificial photosynthesis - a process mimicking the ability of plants to convert sunlight into energy. It is based on an advanced 'photosheet' technology and converts sunlight, carbon dioxide and water into oxygen and formic acid - a storable fuel that can be either be used directly or be converted into hydrogen.

The results, reported in the journal Nature Energy, represent a new method for the conversion of carbon dioxide into clean fuels. The wireless device could be scaled up and used on energy 'farms' similar to solar farms, producing clean fuel using sunlight and water.

Harvesting solar energy to convert carbon dioxide into fuel is a promising way to reduce carbon emissions and transition away from fossil fuels. However, it is challenging to produce these clean fuels without unwanted by-products.

"It's been difficult to achieve artificial photosynthesis with a high degree of selectivity, so that you're converting as much of the sunlight as possible into the fuel you want, rather than be left with a lot of waste," said first author Dr Qian Wang from Cambridge's Department of Chemistry.

"In addition, storage of gaseous fuels and separation of by-products can be complicated - we want to get to the point where we can cleanly produce a liquid fuel that can also be easily stored and transported," said Professor Erwin Reisner, the paper's senior author.

In 2019, researchers from Reisner's group developed a solar reactor based on an 'artificial leaf' design, which also uses sunlight, carbon dioxide and water to produce a fuel, known as syngas. The new technology looks and behaves quite similarly to the artificial leaf but works in a different way and produces formic acid.

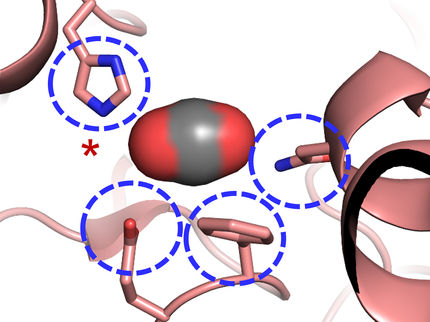

While the artificial leaf used components from solar cells, the new device doesn't require these components and relies solely on photocatalysts embedded on a sheet to produce a so-called photocatalyst sheet. The sheets are made up of semiconductor powders, which can be prepared in large quantities easily and cost-effectively.

In addition, this new technology is more robust and produces clean fuel that is easier to store and shows potential for producing fuel products at scale. The test unit is 20 square centimetres in size, but the researchers say that it should be relatively straightforward to scale it up to several square metres. In addition, the formic acid can be accumulated in solution, and be chemically converted into different types of fuel.

"We were surprised how well it worked in terms of its selectivity - it produced almost no by-products," said Wang. "Sometimes things don't work as well as you expected, but this was a rare case where it actually worked better."

The carbon-dioxide converting cobalt-based catalyst is easy to make and relatively stable. While this technology will be easier to scale up than the artificial leaf, the efficiencies still need to be improved before any commercial deployment can be considered. The researchers are experimenting with a range of different catalysts to improve both stability and efficiency.

The current results were obtained in collaboration with the team of Professor Kazunari Domen from the University of Tokyo, a co-author of the study.

The researchers are now working to further optimise the system and improve efficiency. Additionally, they are exploring other catalysts for using on the device to get different solar fuels.

"We hope this technology will pave the way toward sustainable and practical solar fuel production," said Reisner.

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.