3D Laser Printing in Color

Seasoning with Nanosilver

Advertisement

Ventilation grilles in aircraft cabins, serial components in cars and lately even mascara brushes: The industry has been using laser-based 3D printers for several years now when precision and good mechanical properties are required. However, these printers are expensive, large and print only in white. For home use, desktop devices are becoming available, but they can only print in black – until now. A team from the Center for Nanointegration (CENIDE) at the University of Duisburg-Essen (UDE) has now brought color into play.

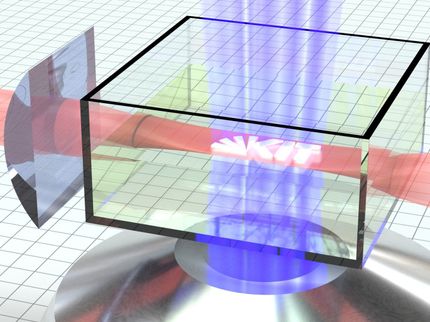

In their publication, the scientists have called it "seasoning" in a winking way and arranged the bowls accordingly: They contain the powder raw material, coated with different nanoparticles for laser-based 3D printing in various colors.

© Gökce, CENIDE/UDE

The laser printers for the kitchen table are to become cheaper and smaller – and more colorful: "Instead of the CO2 lasers commonly used in the industry, we are relying on much cheaper diode lasers, such as those with lower output found in CD players," explains Dr. Bilal Gökce from Technical Chemistry I at UDE. "However, you have to be a little tricky." Because the usual polymer powder, the raw material for printing, is white. This means that it reflects all the wavelengths of the visible light – unfortunately including those of diode lasers.

That's when the team had the idea to kill two birds with one stone: The scientists coated the powder grains with nanoparticles made of silver. The point is: In the tiny dimensions of a millionth of a millimeter, materials often have surprising properties. For example, silver appears yellow, while nanogold is red to violet.

Concept Applicable to Other Colors

The previously white polymer was now yellow, and in combination with a diode laser, whose radiation is particularly well absorbed by yellow objects, the idea worked. The result was the first laser-based desktop 3D printing in color – to be read in the current issue of Advanced Optical Materials magazine, which featured the article in its cover.

"Since the nanoparticles sit firmly on the surface of the powder grains and are not just mixed in, even a pinch of them gives a homogeneous color," Gökce says. And what works with silver also works with nanoparticles of other elements. There are no limits to the colors in this process. As a bonus, you also obtain other characteristics of the nanoparticles as well, such as the antibacterial effect of silver or the magnetic properties of iron oxide.