Fastest sensor for heat flow tested

Relevant for alternative fuels and hydrogen

Advertisement

A team of researchers from the Faculty of mechanical engineering at Landshut University of Applied Sciences has developed a new method to measure the heat flow in combustion engines faster than before. The technique could help reduce pollutant emissions in the future. It is also relevant for the future investigation of alternative fuels and hydrogen-based drives.

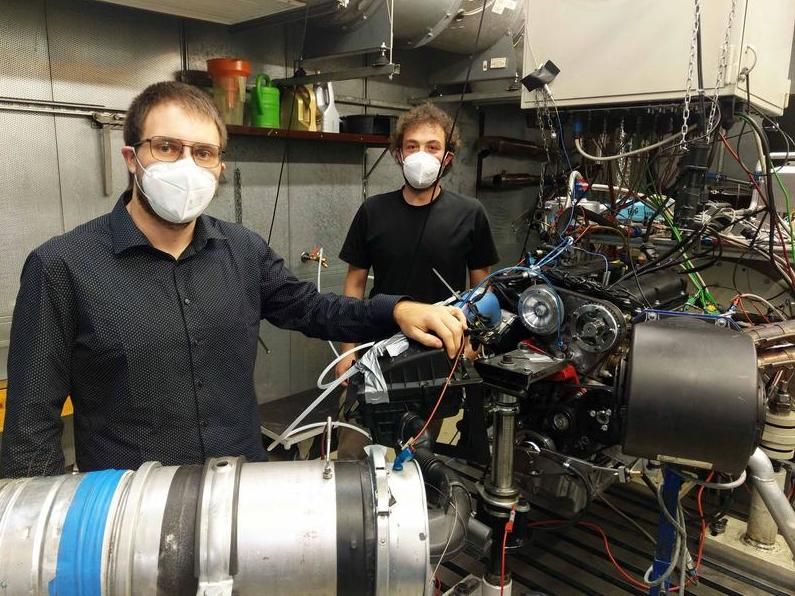

Research assistants Konstantin Huber (left) and Felix Gackstatter (right) at the highly instrumented engine test bench of Spiess Motorenbau GmbH.

Hochschule Landshut

When we start the engine of a car, combustion gases with very high temperatures of more than 1,000 degrees Celsius are produced. When these hit the cylinder and piston walls, very high heat loads occur that are normally only rarely reached, such as during the re-entry of a space shuttle into the earth's atmosphere. Part of the heat energy is dissipated via the combustion chamber walls, resulting in impure combustion near the walls and the formation of soot particles. Under the direction of Prof. Dr. Tim Rödiger, a team of researchers from the Landshut University of Applied Sciences, in cooperation with the engine manufacturer Siegfried Spiess GmbH, has now developed a probe with which this heat flow can be determined directly and without detours via a temperature or pressure measurement. Thus, the new technology enables a ten to one hundred times faster measurement than before. In the future, the method developed in the ALTPdev project could help to improve combustion processes and thermal models of engines and thus reduce emissions of pollutants. The new technology is also relevant for the future investigation of alternative fuels and hydrogen-based drives. The Federal Ministry for Economic Affairs and Energy funded the Landshut University of Applied Sciences with 220,000 euros for the project, which was completed in July of this year.

Test in the engine test bench

Together with research assistants Konstantin Huber and Felix Gackstatter and industrial partner Spiess, Rödiger carried out the measurement campaign on a test bench on a specially prepared engine block. "We refer to the part of the energy that is dissipated via the walls of the combustion chamber as the heat loss flow," Rödiger explains, drawing a comparison with human skin. Our skin, he says, is also a kind of heat flow sensor: "We can tolerate sauna air at 90 degrees Celsius just fine, but the skin would scald on contact with 90-degree hot water." This is related to the heat flow, which is significantly higher in water than in air.

Peak loads measurable for the first time

Very high heat loads can occur in the internal combustion engine. "The reason for this is the rapid course of the ignition and combustion process," explains Rödiger, "which means that very high heat flows can occur for a short time." With the help of the new ALTP sensor (ALTP stands for atomic layer thermopile), it is now possible for the first time to determine these in even greater detail. "In the process, the measurements show that the peak loads could be far higher than previous studies and models predicted," says the professor.

Relevant for alternative fuels and hydrogen

The new method could benefit manufacturers of engines and other combustion systems in the future, from the mobility to the energy sector. "The new technology provides us with information that allows us to better understand the complex processes of combustion; for example, it can be used to develop better predictions of pollutant formation and component wear," Rödiger emphasizes. In addition, the measurements could help improve engine and combustion control in the future, as well as develop new engine concepts and more efficient models. "The information is particularly relevant for the study of alternative fuels," says the professor. For example, hydrogen flames in engines and gas turbine combustors achieve even higher temperatures and burn much closer to the wall, resulting in even higher heat flux densities. This must be taken into account in the development of components in the future, he said.

Measurement in the microsecond range

The new technology measures in the microsecond range, making it the world's fastest method. "Until now, the ALTP method has only been tested for short-term measurements in wind tunnels and test rigs," says Rödiger, "We have modified the technology so that it is easy to apply and can be used for highly stressful cyclic, thermal and mechanical loads. The sensor is installed in the engine block with a direct combustion chamber connection and must therefore withstand both the high temperatures and thermal loads as well as the immense pressure in the combustion chamber. Rödiger emphasizes: "Although we used the sensor technology for our investigations in the combustion engine within the research project, it opens up a wide field of application beyond this area."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.