Mobile test stand for high-resolution Power-to-X kinetic analysis

Time and spatially resolved insight into the reactor

Advertisement

The conversion of renewable power into chemical energy sources through so-called Power-to-X processes is taking on an increasingly important role in Germany’s energy transition. As long-term, easy-to-transport, high-capacity energy sources, PtX maximize the potential of renewable energy and enable the complete transformation of all sectors (power/transportation/agriculture/buildings). Future PtX plants will be built primarily in remote regions offering high potential for renewable energies, or even offshore. For these chemical processes to be possible under such challenging conditions, innovative synthesis reactors and operating strategies are necessary.

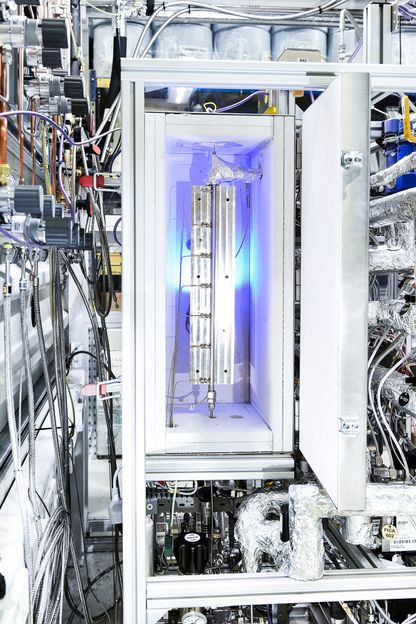

Front view of the reactor with open furnace door. The compact and mobile system is designed for use on location.

Fraunhofer ISE

At the Fraunhofer Institute for Solar Energy Systems ISE, a universally usable test stand for kinetic investigations has been developed to analyze catalytic fixed-bed reactions under dynamic operating conditions. The compact, mobile “KISS” system can also be used on location in remote regions.

The KISS (Kinetic Investigations and Screening Setup) test stand developed at Fraunhofer ISE enables the spatially resolved measurement of concentration profiles and at the same time high-resolution monitoring of the axial temperature profile. A fiber-optic measurement system and a multi-position-valve sampling system in conjunction with a dynamic Fourier transform infrared spectrometer (FTIR) are used for this purpose. “Compared to traditional Kinetic reactors, KISS is unique in terms of the speed of the measurement campaigns as well as the perfect control of the reactor temperature even when the synthesis process generates a lot of heat,” explains Dr. Ouda Salem, Head of Group Power to Liquids at Fraunhofer ISE. In KISS, reactions in both the gas and liquid phase can be investigated. Thanks to the high-performance materials used, KISS can even be used under challenging thermochemical synthesis conditions, enabling the kinetic investigation of a variety of PtX products such as methanol, dimethyl ether, oxymethylene ether, aviation fuels and ammonia. This is of interest to companies that develop new catalysts or chemical processes as well as to research institutions.

Time and spatially resolved insight into the reactor

At the heart of the system is a profile reactor that allows the dynamic measurement of concentration and temperature profiles. By coupling axial sampling points with dynamic FTIR analytics, the product composition can be analyzed at seven positions across the length of the reactor. All relevant reaction parameters are therefore determined in a time and spatially resolved manner. High-precision kinetic models can be developed – even for complex reaction networks.

Combined with the dynamic analysis unit, the extensive automation of the test stand (24/7 operation) allows measurement campaigns to be realized in a minimum of time. Besides kinetic measurement, KISS is also suitable for long-term measurements and measurements involving components that could potentially damage the catalyst and inhibit the reaction. This will bring new insights into the deactivation behavior of catalysts.

Simulation and experiments on one platform

An extensive simulation platform enables the processing of experimental data and its comparison with existing kinetic models. The experimental results and performance of new catalysts can therefore be compared against the state of the art. New kinetic models can be regressed on the basis of the measured profile data. By combining measurement data from the experiment with simulation software, it can be applied to much bigger production scales and much more cost-effective PtX paths as a consequence.

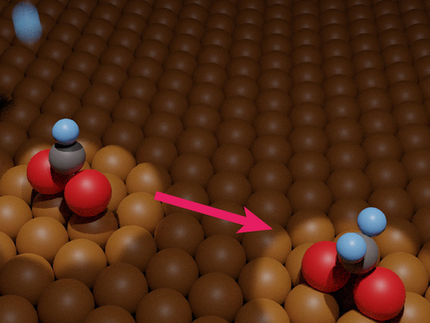

Profile reactor in use: novel dimethyl ether and ammonia synthesis

The test stand has already been used successfully for DME synthesis. Here the reaction takes place in the liquid phase at a moderate reaction temperature, creating new opportunities for process intensification and energy-efficient production. During the measurement campaign, an unexpected dynamic shrinkage of the catalytic bed occurred with the catalyst under investigation. “Thanks to the fiber-optic measurement technology, the shrinkage was quantified in a time-resolved manner based on the shift in the temperature profile in the reactor and as a result included in the modeling. This underlines the added value of KISS compared to traditional kinetic test stands,” reports Malte Semmel, doctoral student in the Group Power to Liquids.

Currently the test stand is being used to investigate ammonia synthesis in a PtX process. Here the focus is on investigating new, more active catalyst materials such as ruthenium-based catalysts. “They offer the potential for the reaction to be realized under much milder reaction conditions. By using the measurement technique described and combining it with the reaction kinetic simulation, reaction kinetic models can be developed and validated for new catalysts even under these challenging conditions,” explains Thomas Cholewa, KISS system developer and doctoral student in the PtL Group. “As a result, the research will be able to make an important contribution to the understanding of ammonia synthesis under the modified conditions of PtX technologies.”

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!