Automation and advanced materials are the “dream team”

Graphene meets robots as automation is combined with advanced materials

Advertisement

Automated systems combined with new materials will combine as a “dream team” to start a revolution in advanced manufacturing, says a graphene pioneer.

Graphene meets robots: pictured is robotics expert Jinseong Park and advanced materials pioneer Dr Vivek Koncherry who are developing a prototype digital manufacturing line at The University of Manchester

The University of Manchester

Automation and robotic systems are on the brink of transforming the way we all work and live says Dr Vivek Koncherry, who is based at The University of Manchester‘s Graphene Engineering Innovation Centre (GEIC). A UK government report has found that the total economic impact of automation across most UK commercial sectors will be worth £6.4bn by 2035.

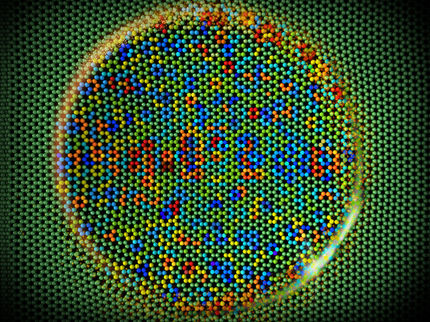

Dr Koncherry and his team are developing a range of products exploiting breakthrough nanomaterial technology, including graphene.

However, to get this innovation to a mass market, Dr Koncherry recognises that manufacturing systems also need to keep pace – so he has built a pilot digital manufacturing line in the GEIC designed to handle materials of the future by integrating robotics, AI and IoT systems.

“The first industrial revolution in Manchester was world famous for its textiles and weaving technologies and we are at the start of the next industrial revolution – but this time we are to use advanced materials and advanced manufacturing processes,” he said.

“So, if you want to implement nanomaterials or the next generation of materials into the marketplace you will also need automation and the next level of advanced manufacturing to remain competitive at a global scale.

“In Manchester, everything comes together – you have expertise in both advanced materials and automated systems. The skilled people we need to work with are based in the same place, which creates a unique proposition.”

This positioning has already helped Dr Koncherry attract inward investment from North America, with $5 million (£3.6m) being put into his start-up Graphene Innovations Manchester (GIM).

Dr Koncherry and his team at GIM, including robotics expert Jinseong Park, are developing a range of products, including mats and floor coverings made from recycled materials - such as rubber from car tyres.

The group are also pioneering pressurised vessels made from a graphene-enhanced composite material. These components can be applied to hydrogen storage on earth or creating a habitat for living in space.

Dr Koncherry has an ambition to grow the manufacturing base in Greater Manchester and from this provide a model to underpin the UK’s national capability to making advanced products.

Other news from the department science

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.