How fine bubbles lead to more efficient catalysts

Newly discovered effect boosts productivity of green hydrogen transport processes

Advertisement

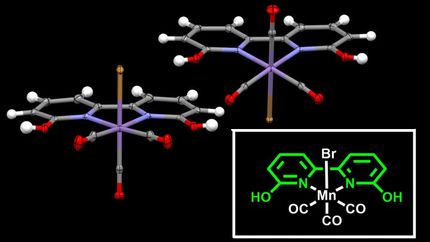

catalysts are of utmost relevance for the production of chemicals and energy storage with hydrogen. Researchers at the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy (HI ERN) and Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) have now discovered that the formation of bubbles in the pores of a catalyst can be essential for its activity. Their findings help to optimize catalyst materials for reactions in which gases are formed from liquids – and which play a central role in a future green hydrogen economy.

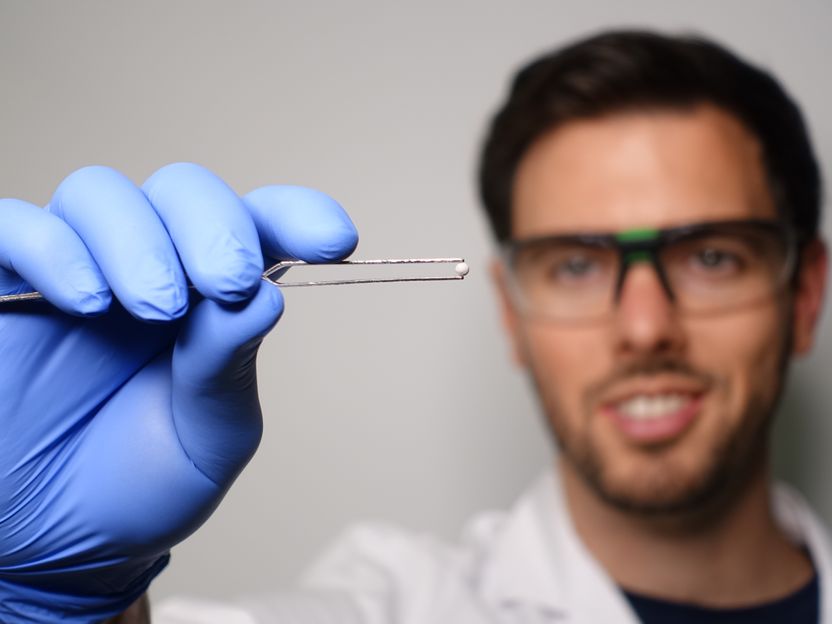

Catalyst pellet for hydrogen release

HI ERN / Thomas Solymosi

Catalysts accelerate chemical reactions without being consumed by themselves. A large number of reactions in nature and industry only work thanks to their help. For example, catalysts are used in around 80 percent of all chemical production processes and also play an important role in technologies for the chemical storage of hydrogen.

In most cases, so-called heterogeneous catalysts are involved, which are in a different aggregate state than the actual reaction partners. Solid, porous catalysts are particularly important here, as they can be separated very well from liquid or gaseous reaction products.

Researchers at HI ERN and FAU have now discovered: The productivity of this type of catalysts for gas generation reactions can be markedly increased if gas bubbles form particularly easily in the catalyst pores.

"This additional factor, which significantly determines the reaction rate, was previously unknown. Until now, it was assumed that the reaction rate was determined only by the chemical surface reaction or by the transport of molecules to the active centers of the catalyst," explains Prof. Dr. Peter Wasserscheid, director of the Helmholtz Institute Erlangen-Nürnberg, a branch of the Jülich Research Center, and head of the Chair of Chemical Reaction Engineering at FAU.

Increasing productivity by a factor of 50

The discovery was made using a reaction that could play a key role in the transport of green hydrogen in the future. To this end, hydrogen is stored and transported bound to a liquid carrier medium - in this case LOHC ("liquid organic hydrogen carrier") - and later released from it.

The technology is considered to be extremely safe and easy to handle. The faster hydrogen can be released from the carrier medium with the aid of a catalyst, the more compact and powerful that technology can be used.

The researchers at HI ERN and FAU were able to show that 50 times more hydrogen is released from the carrier medium per unit of time under the same conditions when the formation of gas bubbles in the pores of the catalyst is induced in the process.

The reason for the enormous difference: "Normally, the system produces only dissolved hydrogen during catalytic hydrogen release. Saturation then quickly sets in in the liquid phase around the active centers of the catalyst," says Peter Wasserscheid.

The bubbles in the catalyst pores, on the other hand, act like tiny pumps. They help to remove the released hydrogen. "Once a bubble has formed in a catalyst pore, the growing bubble collects the formed hydrogen. When the bubble then detaches into the surrounding liquid, the loaded hydrogen carrier flows back into the pore and the process starts all over again," Peter Wasserscheid explains the principle.

The formation of bubbles, known as nucleation, can also be induced artificially, for example by chemically modifying the catalyst surface or by a mechanical stimulus. The findings shed new light on performance-limiting factors in heterogeneous catalysis, which are of very high relevance especially for the green hydrogen economy of the future.

The results were obtained in collaboration between the teams of Professors Jens Harting, Matthias Thommes, Nicolas Vogel and Peter Wasserscheid in the DFG Collaborative Research Program 1452 "Catalysis at liquid interfaces" and have just been published in the journal Science Advances.

Original publication

Thomas Solymosi, Michael Geißelbrecht, Sophie Mayer, Michael Auer, Peter Leicht, Markus Terlinden, Paolo Malgaretti, Andreas Bösmann, Patrick Preuster, Jens Harting, Matthias Thommes, Nicolas Vogel, Peter Wasserscheid; Nucleation as a rate-determining step in catalytic gas generation reactions from liquid phase systems; Science Advances (16 November 2022)