Measurement times in materials analysis can be shortened - without loss of accuracy

This saves energy and opens up new potential for industrial applications

Advertisement

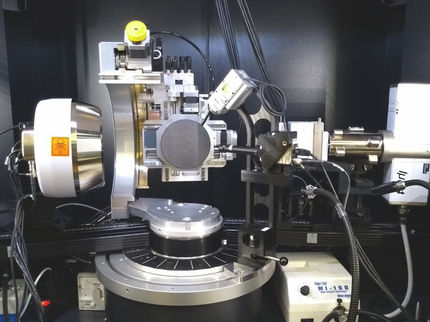

How can the internal structure of a material be analyzed efficiently and the measurement time halved? Researchers at the University of Kassel have found a way to reduce the measurement time of material analysis measurement processes to the necessary minimum - while maintaining the high quality of the results. In energy-dispersive X-ray diffraction (ED-XRD), a method for investigating crystalline material structures, they have been able to reduce the measurement time by up to 62 percent. This saves energy and opens up new potential for industrial applications.

With the growing number of new, reliable and environmentally friendly alloys, the need for precise analysis is also increasing. As a result, existing measuring stations are increasingly reaching their capacity limits. The potential savings identified in a recently published study make it possible to sustainably increase sample throughput - without additional resources. "This is a clear added value, especially in industrial materials development," explains Dr. Alexander Liehr from the Institute of Materials Engineering (IfW), who drove the research project at the Department of Metallic Materials under the direction of Prof. Niendorf. "Faster analyses shorten innovation cycles. This is a decisive advantage for sectors such as the automotive and aviation industries, where high-performance lightweight materials continue to gain in importance."

The method developed is not limited to X-ray diffraction, but can also be transferred to other material analysis methods with corresponding data structures, for example in quality control, alloy development or process monitoring. "It can also be applied to large-scale research facilities, which is particularly advantageous for the efficient use of limited large-scale research facilities," says Liehr.

The aim of the project was to shorten the measurement time using intelligent selection strategies for energy intervals and at the same time obtain reliable information about the microstructure of the material. In order to significantly shorten the measurement time, the interdisciplinary research team tested various methods to record and evaluate only the really decisive data areas. The combination of expertise from materials engineering and computer science, namely the Intelligent Embedded Systems department (IES, headed by Prof. Bernhard Sick), which deals with technical applications of artificial intelligence, was crucial to the success of the project.

The strategies developed use prior knowledge of the materials under investigation to control the selection - and delivered convincing results: The measurement time could be reduced by up to62 percent without sacrificing the accuracy achieved. In view of the growing demands for efficiency and data quality in materials analysis, these strategies offer a promising basis: "They enable automated and resource-saving analysis of even large material series - an important step towards intelligent materials testing," explains Liehr.

The study was published in the journal Scientific Reports (Nature Publishing Group). Based on these results, the successful collaboration is to be continued, intelligent experimentation methodically developed further and transferred to other fields of application.