Inspired by the gecko: Better adhesion properties of plastics through combined micro- and nanostructures

Structured surface improves adhesion, wettability, optical reflection, hydrophobicity and recyclability.

Advertisement

With a patented process for micro-nano-structuring, the Fraunhofer Institute for Microstructure of Materials and Systems IMWS in Halle (Saale) has achieved significant improvements in the adhesion properties of polymers. The process, in which structured surfaces are produced by hot imprinting or injection molding, also offers considerable advantages in terms of wettability, optical reflection, hydrophobicity and recyclability.

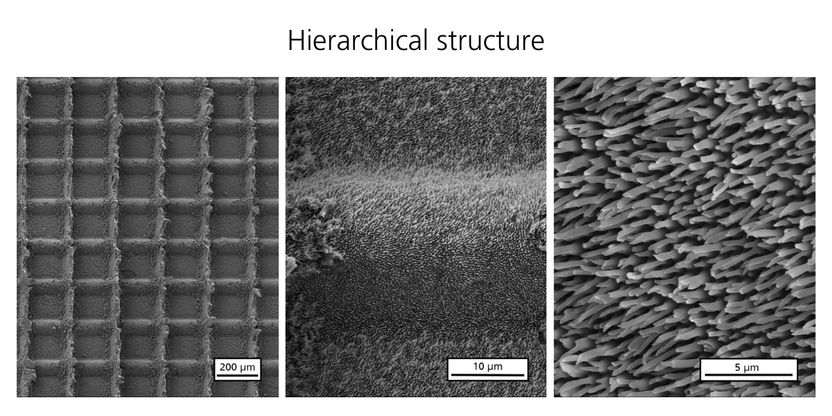

Scanning electron microscope image of the hierarchical structure in a polycarbonate surface.

© Fraunhofer IMWS

When a gecko climbs up walls, it does so thanks to the large contact surface of the hierarchical and fibrillar structures of its feet with the ground. The Fraunhofer IMWS has implemented a similar approach for the surfaces of polymers. These are given a hierarchical structure by hot imprinting, using embossing tools made of aluminum oxide that have previously been micro- and nanostructured using a laser and a self-organizing electrochemical process.

The process is suitable for structuring various plastics such as thermoplastic elastomers (TPE), thermoplastic polyurethanes (TPU), polycarbonate (PC), polymethyl methacrylate (PMMA), polypropylene (PP) or polyethylene (PE). The embossing tools made of aluminum oxide can be easily integrated into existing production processes for plastics processing. Molding takes place at high temperatures and low pressure. After cooling under load, demolding is carried out by removing the polymer material from the embossing tool.

In order to optimize the process, the Fraunhofer team determined the appropriate processing temperatures based on the glass transition and melting temperatures obtained by differential scanning calorimetry (DSC). The micro/nanostructure of the embossing tools and the resulting inverse structure of the polymer surface with the finest nanofilaments was examined using scanning electron microscopy (SEM). On wet surfaces (ceramic, glass, metal), an increase in adhesive strength of up to 85.4 percent was achieved using the Gecko method.

The surface structures can be individually and specifically adapted using appropriately manufactured tools, which opens up a wide range of possible applications. New solutions for the packaging industry to improve the adhesion of glue and printing inks to films are obvious, as are new approaches to prevent plastic surfaces from fogging, for example in the optical industry.

"Another major advantage is that we can achieve different surface structures and thus new material properties without introducing additional elements such as additives or coatings. This means that the materials can remain pure, which considerably simplifies subsequent recycling," says Dr. Andrea Friedmann, Group Manager "Biofunctional Materials for Medicine and the Environment" at the Fraunhofer IMWS. "Lengthy and costly approval procedures are also avoided because micro-nano-structuring is carried out on materials that have already been approved and have not been chemically modified. This allows companies to save a lot of time and high costs when introducing improved products."