Laser-induced graphene gets tough, with help

Combining conductive foam with other materials for capable new composites

Advertisement

Laser-induced graphene (LIG), a flaky foam of the atom-thick carbon, has many interesting properties on its own but gains new powers as part of a composite.

Rice University scientists have combined laser-induced graphene with a variety of materials to make robust composites for a variety of applications.

Tour Group/Rice University

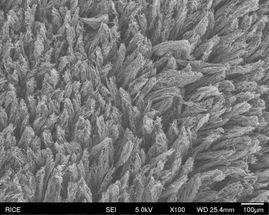

A scanning electron microscope image shows a composite of laser-induced graphene and polystyrene.

Tour Group/Rice University

The labs of Rice University chemist James Tour and Christopher Arnusch, a professor at Ben-Gurion University of the Negev in Israel, introduced a batch of LIG composites in the American Chemical Society journal ACS Nano that put the material's capabilities into more robust packages.

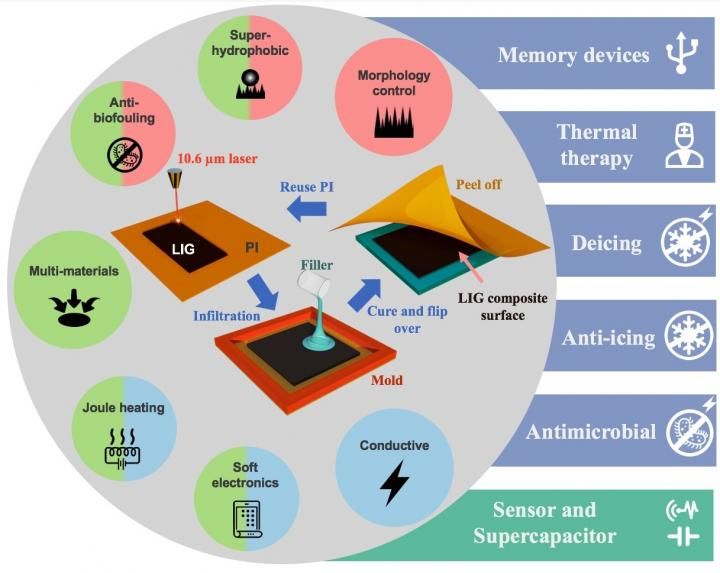

By infusing LIG with plastic, rubber, cement, wax or other materials, the labs made composites with a wide range of possible applications. These new composites could be used in wearable electronics, in heat therapy, in water treatment, in anti-icing and deicing work, in creating antimicrobial surfaces and even in making resistive random-access memory devices.

The Tour lab first made LIG in 2014 when it used a commercial laser to burn the surface of a thin sheet of common plastic, polyimide. The laser's heat turned a sliver of the material into flakes of interconnected graphene. The one-step process made much more of the material, and at far less expense, than through traditional chemical vapor deposition.

Since then, the Rice lab and others have expanded their investigation of LIG, even dropping the plastic to make it with wood and food. Last year, the Rice researchers created graphene foam for sculpting 3D objects.

"LIG is a great material, but it's not mechanically robust," said Tour, who co-authored an overview of laser-induced graphene developments in the Accounts of Chemical Research journal last year. "You can bend it and flex it, but you can't rub your hand across it. It'll shear off. If you do what's called a Scotch tape test on it, lots of it gets removed. But when you put it into a composite structure, it really toughens up."

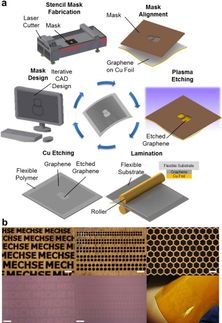

To make the composites, the researchers poured or hot-pressed a thin layer of the second material over LIG attached to polyimide. When the liquid hardened, they pulled the polyimide away from the back for reuse, leaving the embedded, connected graphene flakes behind.

Soft composites can be used for active electronics in flexible clothing, Tour said, while harder composites make excellent superhydrophobic (water-avoiding) materials. When a voltage is applied, the 20-micron-thick layer of LIG kills bacteria on the surface, making toughened versions of the material suitable for antibacterial applications.

Composites made with liquid additives are best at preserving LIG flakes' connectivity. In the lab, they heated quickly and reliably when voltage was applied. That should give the material potential use as a deicing or anti-icing coating, as a flexible heating pad for treating injuries or in garments that heat up on demand.

"You just pour it in, and now you transfer all the beautiful aspects of LIG into a material that's highly robust," Tour said.