U. T. Dallas scientists spin Carbon Nanotube Fibers with record strength and toughness

Breakthrough promises hjost of novel applications, including electronic textiles

Advertisement

nanotechnology researchers at The University of Texas at Dallas (UTD) and Trinity College, Dublin, Ireland, have announced a breakthrough in spinning carbon nanotube composite fibers that are tougher than any reported polymer fiber made by man or nature.

The discovery -- which could lead to many novel applications, from UTD-demonstrated, energy-storing "electronic textiles" and artificial muscles to bullet-proof vests more impenetrable than those now in use--is outlined in an article in the June 12 issue of the prestigious scientific journal Nature.

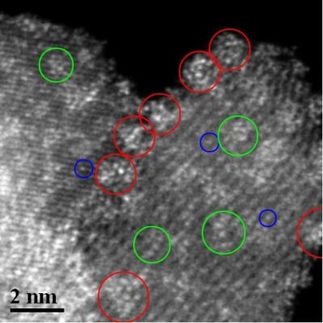

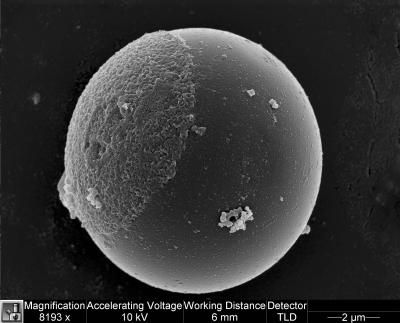

In the article, co-authored by nine scientists, a new process is described for the continuous spinning of composite fibers of carbon nanotubes, rolled-up sheets of graphite that are 50,000 times thinner than a human hair. The toughness, or capability to absorb energy, of the UTD fibers is more than four times that of spider silk and 17 times that of the Kevlar used in bullet-proof vests -- making them what is believed to be the toughest known material. These fibers have twice the stiffness and strength, and 20 times the toughness, of the same weight and length steel wire.

"The remarkable mechanical and electronic properties of individual carbon nanotubes have been known for some time," said the article's corresponding author, Dr. Ray H. Baughman, Robert A. Welch Professor of Chemistry and director of the UTD NanoTech Institute. "However, mankind has largely been unsuccessful in processing untold billions of these invisible nanofibers to make useful articles that exploit these properties. Our spinning method is the first to produce high-performance, continuous fibers of carbon nanotubes suitable for potential use in a wide array of applications."

Among those possible applications, according to Baughman, are:

* Clothing woven from the fibers that could store electrical energy, much like a battery, and be used to power various electrical devices. * Synthetic muscles capable of generating 100 times the force of the same diameter natural muscle. * Distributed fiber sensors able to monitor the movement and health of "first responders" to emergencies. * A power source for spacecraft on long voyages through conversion of thermal energy to electrical energy using nanotube fibers. * A new generation of bullet-proof vests and anti-ballistic materials that are much more effective than those in use today. * Multifunctional fibers for "micro air vehicles" the size of an insect that could replace current, much larger military drones used to gather intelligence remotely.

Other contributors to the pioneering nanotechnology research include Alan B. Dalton, Steve Collins, Edgar Mueuroz, Joselito M. Razal, Von Howard Ebron, John P. Ferraris and Bog G. Kim of the UTD NanoTech Institute, and Jonathan N. Coleman, a visiting scientist from the Department of Physics at Trinity College Dublin, Ireland.

The research described in the Nature article was funded primarily by the Defense Advanced Research Projects Agency, an agency of the United States Department of Defense responsible for the development of new technology for use by the military.

Other news from the department

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.