Removing nitrogen compounds from diesel by adsorption onto copper-containing zeolites

Advertisement

The sulfur and nitrogen compounds found in fuels cause environmentally harmful sulfur and nitrogen oxides to be released on combustion. It is thus becoming more and more important that gasoline, diesel, and kerosene be as free of these materials as possible. Researchers at the University of Michigan have now developed a new method for the removal of unpleasant nitrogen compounds from diesel.

The classic removal of nitrogen from fuels occurs simultaneously with the removal of sulfur by catalytic conversion with hydrogen at high pressures and temperatures. Crude oil contains two classes of nitrogen compounds, heterocycles-carbohydrate rings with one nitrogen atom in the ring-and nonheterocycles-compounds in which the nitrogen is not incorporated into a ring, such as anilines and open-chain amines. While hydrogenation is quite effective at removing the nonheterocycles, the nitrogen heterocycles react too slowly to be effectively removed from the crude oil. Most prominent among the heterocycles are the six-membered ring pyridine and the five-membered ring pyrrole, as well as compounds that contain these aromatic rings as components.

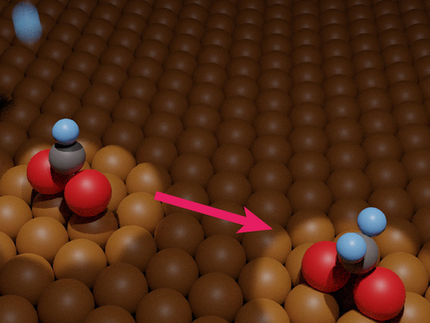

Ralph T. Yang and Arturo J. Hernández-Maldonado searched for an adsorptive method to selectively remove these annoying nitrogen compounds. A screening process led the researchers to a suitable adsorbent, a special zeolite that is loaded with copper ions that have a single positive charge. Zeolites are crystalline, porous silicates with cage-like pores. If aromatic nitrogen compounds get into the zeolite pores, they form complexes with the copper ions. These bind more strongly to nitrogen-containing aromatic compounds than to others, such as benzene and organosulfur compounds.

With the help of the copper zeolite, the nitrogen content of commercially available diesel can be lowered from 83 ppm to under 0.1 ppm (0.1 millionth of a gram per gram of diesel). The adsorption occurs at room temperature and atmospheric pressure, and the adsorbent can be completely regenerated-good conditions for large-scale application.

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.