Degussa-Hüls and Krupp Uhde to cooperate in propylene oxide

Advertisement

he two German companies Degussa-Hüls AG and Krupp Uhde GmbH, headquarted in Frankfurt/Main and in Dortmund, respectively, have concluded an exclusive agreement for cooperating in the development of a new process for the production of propylene oxide. Propylene oxide (PO) is a base chemical with an above-average market growth rate and is used primarily in the production of polyurethane and polyester resin raw materials. Polyurethane is used, for example, in the cushions of auto seats and furniture.

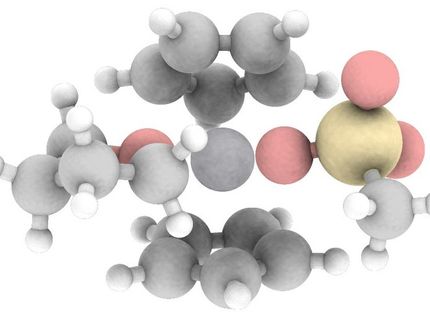

The new process yields propylene oxide by means of the catalytic oxidation of propylene with hydrogen peroxide. As the world’s second largest producer of hydrogen peroxide, and as a research and technology-oriented company, Degussa-Hüls explored the process, developing an optimized catalyst and determining the most important parameters. This know-how, combined with Krupp Uhde's expertise in plant engineering and technology, will generate the basis for further process development as regards commercial-scale production and later commercialization.

As a technology-oriented engineering company, Krupp Uhde is systematically planning the future development and expansion of its portfolio of processes. Particular importance is attached in this respect to propylene and its derivatives. Using this innovative technology, Degussa-Hüls intends to open up new sales potential for hydrogen peroxide.

Currently, propylene oxide is manufactured primarily through the chlorohydrine process and the propylene oxide/styrene monomer process (POSM). In the chlorohydrine process, a chlorine-containing waste liquor is produced; the POSM process generates large quantities of styrene monomer (SM) as a co-product. Besides its lower cost, however, the Degussa-Hüls/Krupp Uhde process has the extra advantage of producing no co-product in the manufacturing process.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.