LAMINAR Product Presentation

Taylor Vortex Flow Chemical Reactor - Lab to Mass Production

Laminar Co., Ltd.

Continuous High Yield Production

Combined Benefits of Batch Reactor and PFR Reactor

High Uniformity in Product Particles and Exothermic Reaction Control Feature

Continuous Chemical Reactor for High Purity and Uniform Materials

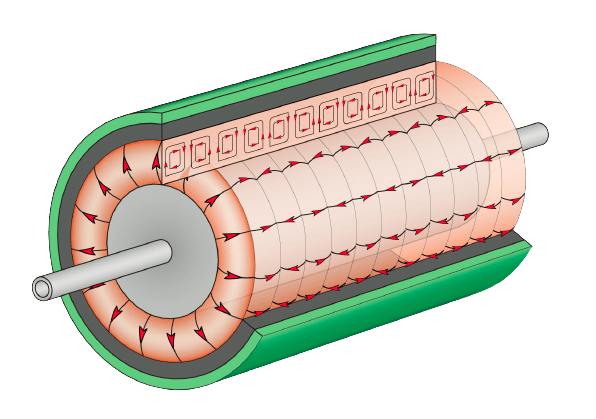

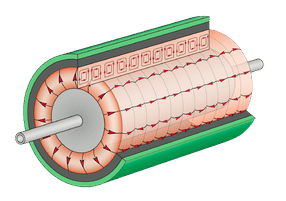

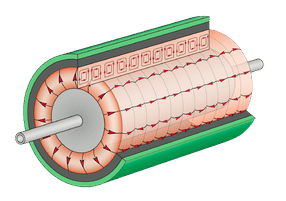

The patented Taylor Flow Chemical Reactor has been widely used by not only laboratories but also companies in the world thanks to its advantages over the conventional CSTR or Batch reactors. The Taylor Reactor can provide faster chemical reaction speed and shorter cycle time, where its mixing force is up to 7 times stronger, and 4 times faster in mass transfer velocity than a similar batch reactor. Not only that, the Taylor Reactor uses homogenous micro-mixing zones to produce high purity products with uniform-sized particles and minimize loss of input materials. Since it brings significant improvements in productivity, purity, uniformity and density, the Taylor Reactors are being used globally for a wide range of applications in the USA, France, Germany and Korea and etc. Have you ever encountered any difficulty in productivity, uniformity, purity and/or density or do you have any plan for a new product development project? If yes, please feel free to contact us for sample test, demo or any advice so that we can help you solve your problem together with the Taylor Reactor!

1

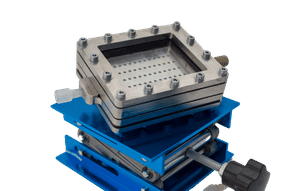

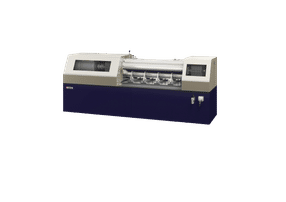

LCTR-LabII-H (Lab)

2

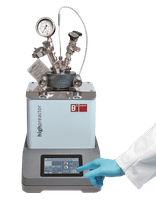

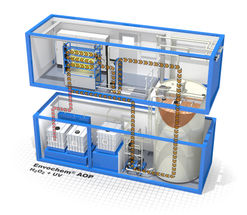

LCTR-Tera (Lab-Pilot)

3

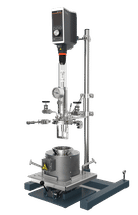

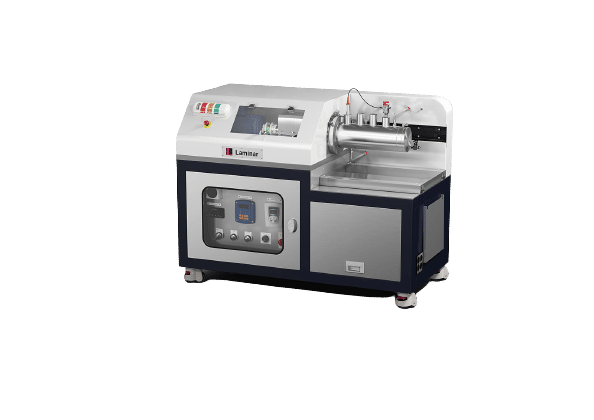

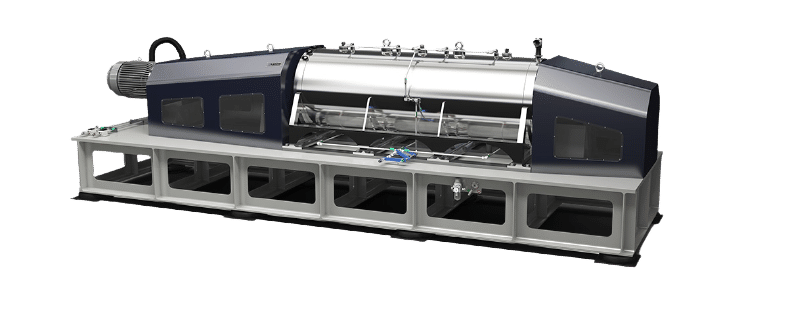

LCTR-Peta (Pilot-Mass Production)

4

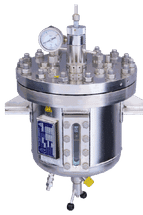

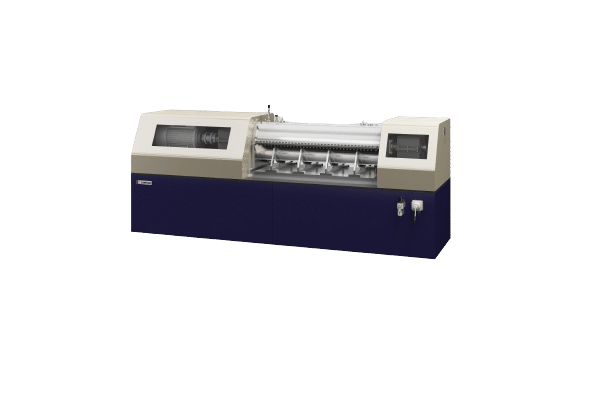

LCTR-Exa (Mass-Production)

5

Taylor flow

Product classification LAMINAR Product Presentation

Applications

Product categories

Target Industries

Request information about LAMINAR Product Presentation now

Reactors: LAMINAR Product Presentation

Taylor Vortex Flow Chemical Reactor - Lab to Mass Production