DSM and Novomer to develop first CO2-based resin for coatings

Advertisement

Royal DSM N.V. and Novomer Inc. announced that they have signed an agreement to jointly develop a revolutionary coating resin using carbon dioxide (CO2) as a raw material. This development agreement follows a cooperation agreement and an investment by DSM Venturing in Novomer in 2007. The joint development project will benefit from the broad variety of DSM's technologies and market access, in combination with the unique, efficient CO2 polymerization technology of Novomer.

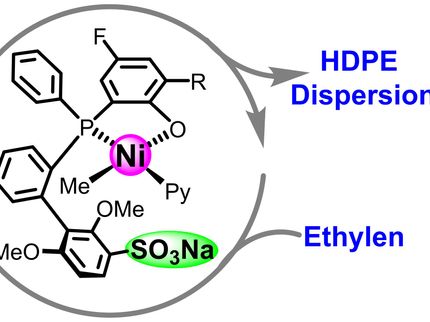

The chemistry and process technology for producing polymers from CO2 and propylene oxide (PO) will be developed by Novomer, while DSM will convert the polymers into resins and formulate them for target applications such as coatings, adhesives and graphic arts. Initial results are encouraging and suggest that this project might lead to completely new and improved application properties in coatings.

Given the fact that up to 50% by weight of CO2 is used as raw material, the production of these resins will result in an improved carbon footprint. The process is also expected to be highly efficient, enabling the replacement of conventional resins in a number of coating applications.

Polycarbonate resins are widely known because of their superior performance and resistances and theoretically could find use in many types of coatings. Commercial use of conventional types has however always been limited due to their cost position and some weaknesses that are inherent in these products. The new CO2-based aliphatic polycarbonates to be developed by DSM and Novomer could potentially resolve these weaknesses.

Rob van Leen, Chief Innovation Officer of DSM, comments: "DSM and Novomer are looking to develop the first polymer in more than a decade to enter the mainstream of the coating industry. This exciting development can lead to a breakthrough that could change the coating industry. Besides cost issues, these innovative coating resins also address environmental and performance issues. They therefore fit in perfectly within DSM's People, Planet and Profit approach."

Most read news

Other news from the department business & finance

These products might interest you

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.