Converting carbon dioxide to valuable resources with the help of nanoparticles

Advertisement

Enzymes use cascade reactions to produce complex molecules from comparatively simple raw materials. Researchers have now copied this principle.

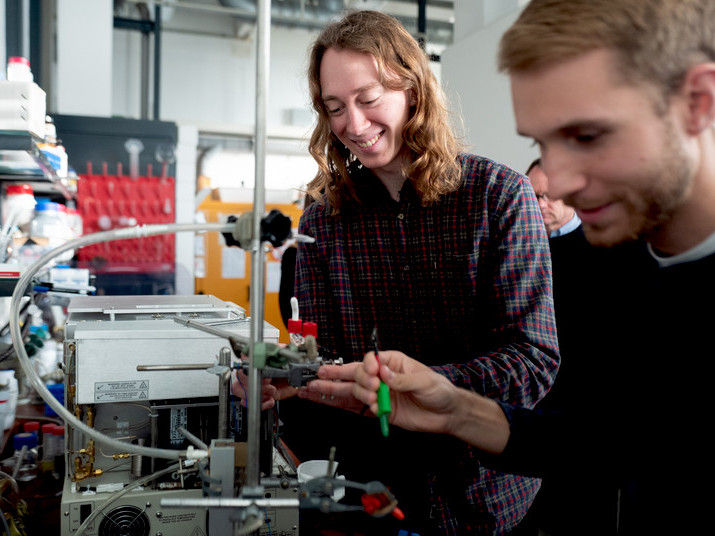

Peter O’Mara from Sydney (on the left) and Patrick Wilde from Bochum working with an electrochemical cell for CO2 reduction

© RUB, Kramer

An international research team has used nanoparticles to convert carbon dioxide into valuable raw materials. Scientists at Ruhr-Universität Bochum in Germany and the University of New South Wales in Australia have adopted the principle from enzymes that produce complex molecules in multi-step reactions. The team transferred this mechanism to metallic nanoparticles, also known as nanozymes. The chemists used carbon dioxide to produce ethanol and propanol, which are common raw materials for the chemical industry.

The team led by Professor Wolfgang Schuhmann from the Center for Electrochemistry in Bochum and Professor Corina Andronescu from the University of Duisburg-Essen, together with the Australian team led by Professor Justin Gooding and Professor Richard Tilley, reported in the Journal of the American Chemical Society on 25 August 2019.

“Transferring the cascade reactions of the enzymes to catalytically active nanoparticles could be a decisive step in the design of catalysts,” says Wolfgang Schuhmann.

Particle with two active centres

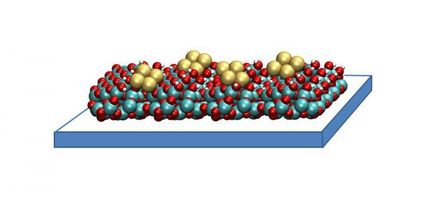

Enzymes have different active centres for cascade reactions, which are specialised in certain reaction steps. For example, a single enzyme can produce a complex product from a relatively simple starting material. In order to imitate this concept, the researchers synthesised a particle with a silver core surrounded by a porous layer of copper. The silver core serves as the first active centre, the copper layer as the second. Intermediate products formed at the silver core then react in the copper layer to form more complex molecules, which ultimately leave the particle.

In the present work, the German-Australian team showed that the electrochemical reduction of carbon dioxide can take place with the help of the nanozymes. Several reaction steps on the silver core and copper shell transform the starting material into ethanol or propanol.

“There are also other nanoparticles that can produce these products from CO2 without the cascade principle,” says Wolfgang Schuhmann. “However, they require considerably more energy.”

The researchers now want to further develop the concept of the cascade reaction in nanoparticles in order to be able to selectively produce even more valuable products such as ethylene or butanol.

Original publication

Peter B. O’Mara, Patrick Wilde, Tania M. Benedetti, Corina Andronescu, Soshan Cheong, J. Justin Gooding, Richard D. Tilley, Wolfgang Schuhmann; "Cascade reactions in nanozymes: spatially separated active sites inside Ag-core–porous-Cu-shell nanoparticles for multistep carbon dioxide reduction to higher organic molecules"; Journal of the American Chemical Society; 2019