How a bath sponge becomes a bio-based industrial filter

New material can be reused many times over

Advertisement

Researchers at TU Bergakademie Freiberg developed an innovative material from a cultured marine sponge. When the fibers of the sponge react with a copper-containing ammonia solution, such as that found in the electronics industry, the mineral atacamite is formed. This mineral, which occurs only very rarely in nature, attaches itself so strongly to the sponge fibers that a robust material is created that has catalytic and antibacterial properties and could therefore potentially be used as a bio-based industrial filter.

Prof. Hermann Ehrlich looks at a piece of the new material.

TU Bergakademie Freiberg / C. Mokry

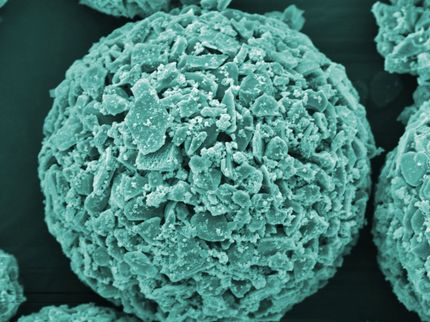

Professor Hermann Ehrlich places a piece of sponge in an alkaline, copper-containing ammonia solution that simulates a copper bath from the manufacture of circuit boards for electronic components. About 12 hours later the sponge has turned blue - when dry it is stronger than before, but still very light. "At a pH value of 9 the fibers of the spongin open and the organic compounds of the protein change," explains Prof. Hermann Ehrlich. The copper contained in the ammonia solution reacts immediately with the organic components of the spongin, especially with the amino acid residues, and forms the mineral atacamite. “Like a string, nanometer-sized crystals grow along with the spongin fiber,” explains the scientist. They stabilize the framework and at the same time ensure that the sponge is retained in its unique micro-architecture.

The team is led by Prof. Hermann Ehrlich. The researchers published the results in a current publication in the journal Advanced Materials.

Can be used as a bio-based filter for wastewater treatment or pollutant removal

The three-dimensional and porous material is inherently a filter. Coupled with the properties of atacamite, there is a wide range of potential for using the new material as an alternative to synthetic filters. "Our team was able to demonstrate experimentally for the first time that the composite material made from marine bath sponges can in principle be used in the development of sensors, catalysts, and antibacterial filter systems," explains co-author Prof. Martin Bertau from the Institute of Chemical Technology at TU Bergakademie Freiberg.

New material can be reused many times over

Does Prof. Hermann Ehrlich puts the blue sponge with the crystals in an acidic solution, the reaction runs backwards: the sponge is back in its original state and can be processed again for further applications. "The newly developed material can therefore be recycled again and again," said the Freiberg biomineralogist enthusiastically.

"Even after up to 100 application cycles, the responsiveness of the spongin-atacamite composite is still given," confirms his colleague Prof. Martin Bertau. “If the material is ultimately no longer usable, the sponge is biodegradable and the copper is recovered from the solution – ideally, electrochemically with renewable energies. We have already shown that this is possible,” says the chemist.