Tea polyphenol-powered strategy revives retired LiFePO₄ cathodes

A low-cost, energy-efficient, and environmentally friendly alternative to traditional metallurgical recycling methods

Advertisement

Researchers from the Institute of Solid State Physics at the Hefei Institutes of Physical Science, Chinese Academy of Sciences, together with the Shenzhen International Graduate School of Tsinghua University and Suzhou University of Technology, have successfully developed a natural electron donor–assisted healing and targeted surface reconstruction strategy that enables the direct regeneration of degraded lithium iron phosphate (LiFePO₄) cathode materials from retired power batteries. Their work, published in Advanced Materials, offers a low-cost, energy-efficient, and environmentally friendly alternative to traditional metallurgical recycling methods.

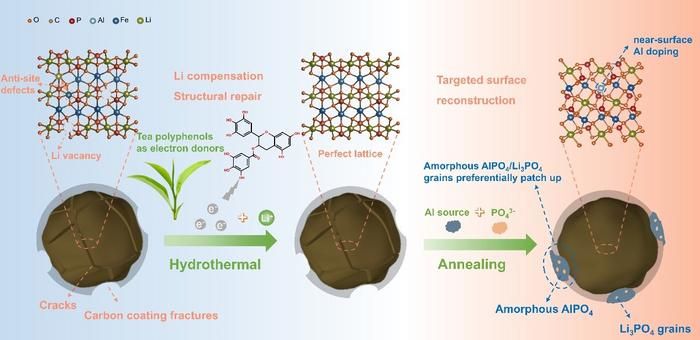

Schematic diagram of direct repair and regeneration mechanism for the retired LiFePO₄ cathodes.

LIU Yuanyuan

As lithium-ion battery usage in new energy vehicles continues to surge, the large-scale retirement of these batteries has raised pressing concerns over environmental pollution and resource wastage. Conventional hydrometallurgical and pyrometallurgical recycling methods can only extract valuable metal elements, making them economically unfeasible for LiFePO₄ cathodes. In contrast, direct regeneration technology can restore degraded cathode materials more efficiently and sustainably.

In this study, the team used naturally extracted tea polyphenols as electron donors. Through the synergistic effect of hydroxyl electron donors and supplemental lithium salts, they successfully converted the degraded FePO₄ phase back to LiFePO₄ and reduced harmful Li–Fe anti-site defects, fully restoring the composition and structure of the material and reconstructing rapid Li⁺ diffusion channels.

To repair damaged or missing surface carbon layers on degraded LiFePO₄ particles, the researchers introduced an aluminum source during the regeneration process. Benefiting from the strong binding affinity between aluminum phosphate (AlPO₄) and LiFePO₄, a targeted composite coating of amorphous AlPO₄ and Li₃PO₄ formed precisely at damaged regions. These fast ion conductors, combined with residual carbon, rebuilt efficient dual electron–ion transport channels on the surface, improving the rate performance of the regenerated cathode. Meanwhile, partial Al doping into the bulk phase enhanced structural stability without reducing energy density, effectively suppressing iron ion migration and extending the service life of the regenerated LiFePO₄ cathodes.

This work provides valuable insights into the recycling of retired power lithium-ion batteries, according to the team.

Original publication

Yuanyuan Liu, Jin Bai, Ruyu Shi, Peiyao Wang, Ke Xiao, Siya Wang, Shiyu Qiu, Xianlong Wang, Xuebin Zhu, Kaishuai Yang, Guangmin Zhou, Bangchuan Zhao, Yuping Sun; "Direct Recycling of Degraded LiFePO4 Cathode Material via Natural Electron Donors Healing and Targeted Surface Reconstruction"; Advanced Materials, 2025-9-13

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.