Invisible secret codes from the 3D printer

Materials that react specifically to temperature: a development by TU Wien has now significantly expanded the range of applications for 3D printers.

Advertisement

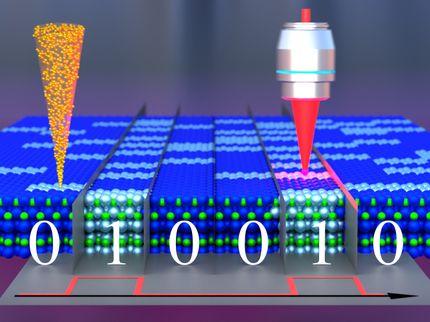

3D printing is extremely practical if you want to produce customized components in small quantities. However, the technology has always had one major problem: 3D printers can only ever process a single material. Objects that have different material properties in different places were previously very difficult or impossible to produce using 3D printers.

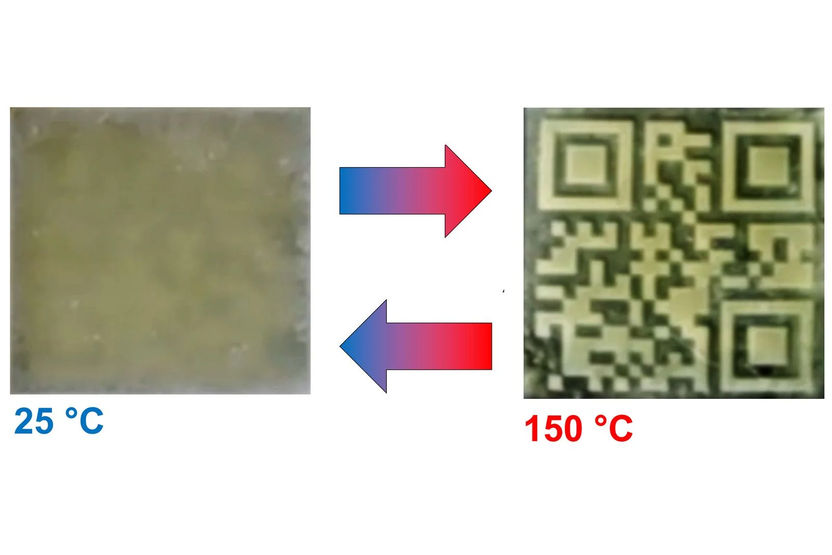

The invisible code: Depending on the temperature, you only see an inconspicuous material - or a QR code

© TU Wien

However, methods have now been developed at TU Wien to give a 3D-printed object not only the desired shape, but also the desired material properties point by point. The versatility of this technology has been demonstrated in several applications: for example, it is possible to print an invisible QR code that only becomes visible at certain temperatures. The results have now been published in the renowned journal "Nature Communications".

Different material properties point by point

Katharina Ehrmann's research team at the Institute of Applied Synthetic Chemistry at TU Wien works with liquid materials that are irradiated with light. A chemical reaction is triggered exactly where the light hits the liquid. The molecular building blocks in the liquid bind together and the material becomes solid.

What is new is that it is now possible to control exactly how the liquid hardens and what properties the resulting material has. "We can use different light intensities, different wavelengths or different temperatures," says Katharina Ehrmann. "All of this can be used to influence the properties of the 3D-printed material."

In this way, it is possible to control how the molecular building blocks in the liquid bond together when they become a solid object. They can arrange themselves regularly, like straight spaghetti in a packet and form a crystal, or they can lie amorphous and disordered, like cooked spaghetti on a plate.

"Depending on the crystallinity, the material properties are also very different," explains Michael Göschl. "Crystalline materials tend to be hard and brittle, while amorphous materials can often be soft and elastic. The optical properties can also vary greatly, from glass-like transparent to opaque white," says Dominik Laa. Michael Göschl and Dominik Laa are the first authors of the current publication and are part of Katharina Ehrmann's and Jürgen Stampfl's research teams.

The invisible QR code

The team has now been able to demonstrate the versatility of the new method in several examples. For example, a QR code was generated inside a piece of plastic, which is covered by a crystalline layer. However, this layer is adapted in such a way that it loses its crystallinity at a certain temperature and becomes transparent - the secret QR code suddenly becomes visible. Depending on the material and temperature, it is also possible to make the QR code unreadable for a certain period of time if the wrong temperature is used to decode it - just like you cannot use a cell phone for a certain period of time if you enter the wrong code three times in a row.

In the same way, a warning symbol could be printed that only becomes visible if the material has been heated above a certain temperature. This makes it possible to check whether the prescribed temperature range has been exceeded when transporting heat-sensitive goods, for example.

The optical characterization of the material was also carried out at TU Wien - in the research group of Prof. Andrei Pimenov at the Institute of Solid State Physics.

"We are offering a completely new range of possibilities for 3D printing here," says Katharina Ehrmann. "Possible applications are foreseeable in many different areas, from data storage and security to biomedical applications."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.