How to filter pathogens, drug residues and microplastics from wastewater

Osnabrück University of Applied Sciences researches membrane technology for wastewater treatment plants

Advertisement

wastewater treatment in sewage treatment plants is essential for environmental and health protection. Before treated water can be discharged into rivers or lakes, it must meet strict quality requirements. These stipulate, for example, exactly how much carbon or nitrogen may still be present. While organic substances such as carbon can be reliably biodegraded, drug residues, hormones, multi-resistant germs and viruses as well as microplastics pose particular challenges for conventional wastewater treatment plants.

Osnabrück University of Applied Sciences is therefore currently working with MANN+HUMMEL Water & Fluid Solutions GmbH to research membrane modules that are used in membrane activation reactors. "This process offers many advantages. In addition to a very high effluent quality of the treated water and a lower space requirement in the wastewater treatment plants, bacteria, viruses, microplastics and some drug residues are reliably retained," says Prof. Dr. Sandra Rosenberger, Professor of Sustainable Energy Technology and head of the project at the university.

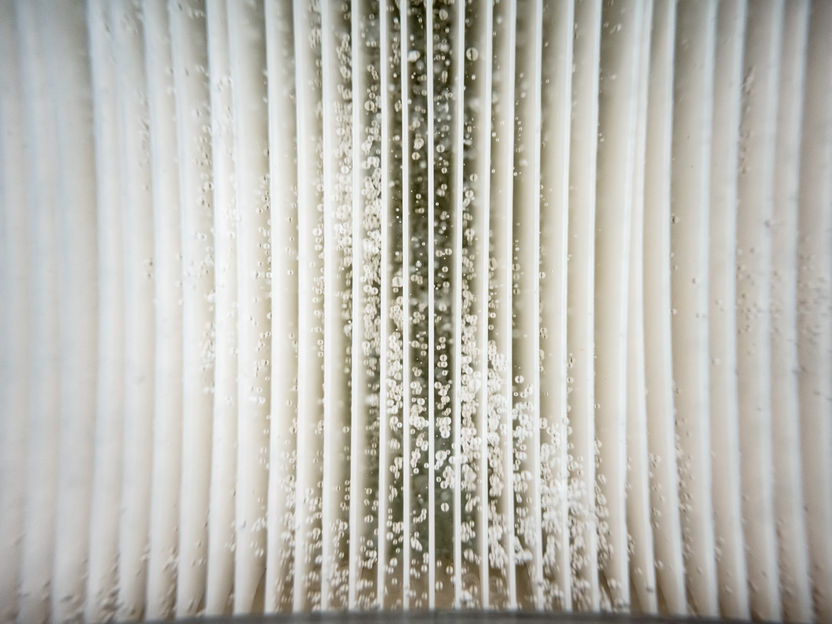

Research on membrane activated sludge reactors: optimized flow control and aeration with air bubbles are intended to prevent deposits on the membrane surface and reduce energy consumption

Hochschule Osnabrück

Wastewater treatment: Multi-stage process for clean water

Wastewater treatment takes place in several stages. First, coarse solids are removed. This is followed by purification in aeration tanks, in which microorganisms break down the organic substances contained in the wastewater. These microorganisms must then be separated from the purified water. Conventional wastewater treatment plants use sedimentation for this purpose: they wait until the microorganisms settle to the bottom of the secondary clarifiers by gravity and separate the clarified water above them.

Membrane modules can also be used instead of secondary clarifiers. Here, porous membranes take on the task of retaining microorganisms and tiny particles such as bacteria or microplastics and separating them from the treated wastewater.

Reducing costs and solving technical problems

"Although membrane activated sludge reactors have been discussed since the 1990s, they have so far only been used where extremely high demands are placed on water quality or where there is not enough space for large secondary clarifiers or plant expansions. The reason for this is the comparatively high costs," says Rosenberger. "In addition to the costs, there are also technical challenges: The fine membranes easily become clogged with sludge particles and therefore have to be cleaned mechanically and chemically on a regular basis."

In order to make the process more economical and energy-efficient, the university is working with membrane manufacturer MANN+HUMMEL Water & Fluid Solutions GmbH. A central issue is the avoidance of deposits on the membranes and the reduction of energy consumption due to the aeration required for this. In current investigations, circulation flows through air bubbles are used to reduce deposits. The project team is researching the optimization of flow control and aeration in order to make these processes more efficient. A glass basin with a capacity of nine cubic meters of water, in which the membrane modules are inserted, is available for the necessary experiments.

Cooperation between industry and university: accelerating research

"The expertise and technical equipment at Osnabrück University of Applied Sciences enables us to investigate different module configurations and aeration systems in detail. Furthermore, the glass tank allows us to visualize the flows and air bubbles within the reactor. This is not possible in real operation at the wastewater treatment plant, but is a considerable added value for research," says Andreas Fischer from MANN+HUMMEL Water & Fluid Solutions GmbH.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.