New method for record-breaking polymer membranes

Fivefold increase in performance through gentle treatment

Advertisement

Scientists from the Institute of Polymer Research at the Helmholtz-Zentrum Geesthacht (HZG) develop tailor-made membrane materials based on thermally rearranged polymers. The researchers recently managed to create the membranes at 250 degrees Celsius rather than at 450 degrees. This represents a breakthrough as the new materials have both an impact that is five times higher and a doubled rate of synthesis. The new polymer for membranes is also less brittle.

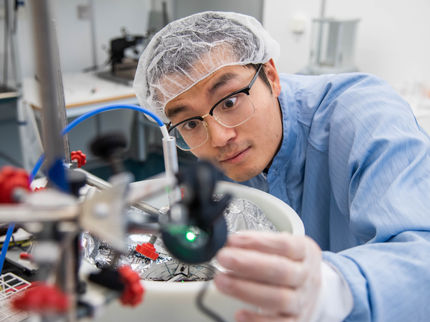

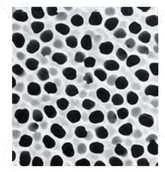

Scientists at the Institute for Polymer Research have developed a new manufacturing process for membrane materials. The new membrane has a five times higher permeability compared to conventionally thermally produced material.

Christian Schmid/HZG

Individual components can be separated from fluid and gaseous mixtures with the help of membranes. Carbon dioxide, for example, can be removed from combustion gases, or pollutants can be filtered from waters. The new membrane materials chemically belong to the polyimide substance group. Certain organic groups are converted to more stable chemical forms during the temperature treatment. Prof Volker Abetz, director of the Institute of Polymer Research and co-author of the publication says, “The new compound is ideal for a variety of gases that need to be separated."

Conventionally produced membranes are usually brittle and break easily. The HZG scientists therefore changed the chemical structure as well as a number of production parameters in order to improve the conditions of the thermal rearrangement. By first utilising what is known as a Claisen rearrangement, the necessary temperature was lowered for the thermal rearrangement from approximately 450 degrees Celsius to approximately 250 degrees. Simultaneously, the rearrangement rate could thereby even be increased by fifty percent compared to conventional synthesis.

Volker Abetz says, “The new thermally rearranged polymers are mechanically and chemically very stable while showing a fivefold increase in permeability in comparison to material that is produced conventionally using thermal methods." In addition, thin-film composite membranes can be produced through the lower rearrangement temperatures for the first time. This has failed in the past because the usual support materials required would be completely destroyed at the 450 degrees used in conventional synthesis.

Overall, the membranes gain enormous appeal with the new generation of polymer materials: the lower production temperatures and the improved separation properties make these new membranes commercially relevant for the first time. The Helmholtz scientists are certain that they have thus managed to get the membrane materials of the future off the ground.